Beisler 1265-5 Operating Instructions Manual

- Typ

- Operating Instructions Manual

1265/5

Single-head se wing unit for serging and

overlocking for trou sers with knee li ning

Operating Instructions

Installations Instructions

Service Instructions

Frohn rad stra ße 10, D-63768 Hös bach

Telefon Ser vice +49 (0) 60 21/ 50 19 40 Telefax +49 (0) 60 21/ 54 00 61 E-mail: Vertrieb@beis ler-gmbh.de

1

2

3

Aus ga be / Edi ti on: 01/2007 Prin ted in Fe de ral Re pub lic of Ger ma ny Tei le-Nr.:/Part-No.:

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the

machine/sewing unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair and/or

– Transport.

The user also has to assure that only authorized personnel work on

the machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including

the performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be

remounted directly after completion of the maintenance and repair

work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

instruction book and operated by persons with appropriate

training.

2. Before putting into service also read the safety rules and

instructions of the motor supplier.

3. The machine must be used only for the purpose intended. Use of

the machine without the safety devices is not permitted. Observe

all the relevant safety regulations.

4. When gauge parts are exchanged (e.g. needle, presser foot,

needle plate, feed dog and bobbin) when threading, when the

workplace is left, and during service work, the machine must be

disconnected from the mains by switching off the master switch or

disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance

unit.

Exceptions to this are only adjustments and functions checks

made by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time

as the entire sewing unit is found to comply with EC directives.

It is absolutely necessary to respect

the safety instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Index Page:

Preface and generalsafetyinstru c tions

Part1: O perating instru c tions cl.1265/5

1. D escription ofproduct.......................................... 3

1.1 D escription ofproperuse ......................................... 3

1.2Briefdescription............................................... 3

1.3 Technicaldata................................................ 4

2. O ptionalequipm ent(see annex) .................................... 5

3. Sw itc h ing on -Sw itc h ing off-Program stop ............................ 6

3.1Switchingon ................................................. 6

3.2Switching off................................................. 6

3.3 Program stop ................................................ 7

3.4Restartafterprogram stop ........................................ 7

4. O peration ofthe sew ing m achine head ............................... 8

4.1 G eneralnotes

......................................................... 8

4.2 R ecom m ended threads .......................................... 9

4.3 R em oving /P utting on the fabricsliding sheet............................. 10

5. O peration ofthe sew ing unit...................................... 11

5.1 Footsw itch m achine sequence ...................................... 11

5.2 Feeding the trousers parts and starting the sew ing operation ................... 11

5.3Adjusting the edge guide ......................................... 13

5.4Adjusting the blow ing airforthe nozzles inthe tabletop ...................... 14

5.5Stackers ................................................... 15

5.5.1Standard stacker.............................................. 15

5.5.2 Throw -overstacker............................................ 16

5.5.3Alternating stacker ............................................ 17

5.6Fusing station (optional).......................................... 18

5.6.1Inserting adhesive tape .......................................... 18

5.6.2Switching the fusing station on and off................................. 18

5.6.3Fusing ofknee lining and fronttrousers................................. 19

5.6.4Clening the stamp.............................................. 20

5.7 Feeding the trousersparts and starting the sew ing operation in conjunction w iththe fusing station 21

6. O peration ofthe control......................................... 23

6.1 O peratorterm inal.............................................. 23

6.2Userinterface ................................................ 24

6.2.1 M enu stru c ture ofthe sew ing and settingprograms......................... 24

6.3Mainscreen ................................................. 26

1

Index Page:

6.4 Seam programs ............................................... 27

6.4.1Factory-setprogram s........................................... 27

6.4.2Selecting the seam program ....................................... 28

6.4.3 M anualsew ing,contro lled viafootpedal ............................... 28

6.4.4 C hanging the program functions .................................... 29

6.4.4.1Quick adjustm entofthe m ain param eters viathe inputfields .................. 29

6.4.4.2 A ccess tothe w hole param eterlistofa seam function ...................... 30

6.4.4.3Switching a seam orm achine function on and off ......................... 30

6.4.4.4 Seam -specific param eters inthe access level1 .......................... 31

6.4.4.5 Seam -specific param eters inthe access level2 .......................... 40

6.5 Seam sequences .............................................. 43

6.6 Preseams................................................... 45

6.7 Seam starting mode ............................................ 46

6.8Activating the sew ing m otor........................................ 46

6.9 R esetting the dailypiece counter .................................... 46

6.10 Input/O utputtest.............................................. 47

6.11 Program m ing m enus ............................................ 49

6.11.1 G eneralnotes ............................................... 49

6.11.2Allocatingafre e s torage location.................................... 49

6.11.3F1=INIT Param eter ........................................... 49

6.11.4 F2 = Mem oryCard............................................. 51

6.11.5F3=Diagnostics.............................................. 53

6.11.6 F5 = Additionalprogram s ........................................ 54

7. M aintenance ................................................ 56

7.1Cleaning and checking........................................... 56

7.2Oillubrication ................................................ 58

1

1. D escription ofproduct

1.1 D escription ofproperuse

The 1265/5isasewing unitw hich can properlybeusedforsew ing

lightto m edium -w eightm aterial.S uch m aterialis,as a rule,m ade of

textilefibres.These m aterials are used inthe garm entindustry.

In generalonlydrymaterialm ustbe sew n on this m achine.The

materialm ustnotcontain any hard objects.

The seam is generally m ade w ithcorethread,polyesterfibre

orcotton threads.

The dim ensions forneedle and hook threads can be taken fro m the

tablein chapter 4.2.

Before using any otherthreads itis necessary toestimatethe

consequentialdangers and totake the respective safety m easures,if

required.

Thissewing unitm ustonlybeinstalled and operated in dry and

well-keptroom s.Ifthe sew ing unitisusedinotherroom s,w hich are

notdry and w ell-kept,furtherm easures to be agreed upon m ay

becom e necessary (see E N 60204-31 :1999).

W e,as m anufacturerofindustrialsew ing m achines,assum e thatat

leastsem i-skilled operating personnelw illbe w orking on ourproducts

so thatallusualoperations and,w here applicable,theirrisks are

presum ed to be know n.

1.2Briefdescription

The Beisler1265/5isasingle-head sew ing unitforserging oftrousers

partswith and w ithoutknee lining.The overlocking ofthe seatand fly

bow as w ellas ofthe trousers hem can be integrated.

Optionally you can w ork w ithorwithouta hotfusing station (lining on

top /lining below ).

Allsew ing unitcom ponents are m ounted on a stand w elded ofsquare

steeltubes and contro lled by a m icroprocessor system .

The sewing unitis operated viaacontrolpanel.H ere itis possibleto

callup various controlprogram s,to define new program s and to check

allinputs and outputsform aintenance and repairpurposes.

M achine head

–

Pegasus two-orthree-thread overlock m achine

EXT 5204-02 w ithtop feed

–

Separatestep m otorcontro l fortop feed and differentialfeed,for

setting the desire d lining fullness,also forstre tch fabrics

–

Microprocessorcontro l,freely program m able

–

Sewing drive E fka D C 1500

–

Autom aticfullness distribution atthe side seam and crotch seam ,

program m able

–

Height-adjustable edge guide fordifferentm aterialthicknesses

–

Autom atic contourguide,contro lled viastep m otor

–

Ejectorviastep m otorforprecise chain separating and positioning

the trousers before stacking

3

–

Step m otorcontro l w ith auxiliary feed forw ide and difficult

materials

–

Processing ofknee lining w ithoutfusing device forcut-to-size knee

lining

–

Optionalfusing unit

–

Lightbarrierforrecognizing the seam beginning and seam end for

autom aticsewing startand stop

–

Verticalcutterw ithsuction foroverlocking and serging in one

operation

–

C hain separating device w ithsuction,program m able

–

Adjustableblow ing nozzles inthe tabletop forsupporting the

materialfeed

–

Height-adjustablestand,infinitelyvariablefrom 850 m m to

1200 m m

–

Integrated stacking device

1.3 Technicaldata

Machine head: Pegasus EXT 5204-02

Stitch type: 504/505

N um berofneedles: 1

N eedle system : B27

N eedlesize: N m 80 toNm110

Threads: see table chapter4.2

Speed: 7000 r/m inwithoutlining

6500 r/minwithlining

Speed upon

delivery: 6500 r/m in

Stitch length:m in. 1.0mm

max. 5.0mm

Seam w idth: 6 m m

Material:Lightto m edium -w eightm aterial

O perating pressure: 6 bar

Airconsum ption: 20 N L perw orking cycle

Rated voltage: 1 x 230 V 50/60 H z

Rated load: 0.9kVA

Dim ensions: 1500 x 900 x 1400 m m (L x W x H )

Working height: 850...1200 m m

(uppertabletop edge)

Weight: 120 kg

4

1

5

Noise value: LC = 81dB (A )

W orkstation-specificemission value according toDIN 45635-48-B-1

Stitch length: 3 m m

Seam length: 1160 m m

Speed: 7000 r/min

MaterialG 1 D IN 23328: 1 layer

M easuring pointaccording

toDIN 4895 part1 X = 600 m m Y = 350 m m Z = 600 m m

X-axis=atrightangles tothe feeding direction

Y-axis=mainfeeding dire c tion

Z-axis = height

2. O ptionalequipm ent

See annex.

3. Sw itching on -Sw itching off-P rogram stop

3.1Switching on

–

Switch on m ainswitch1(turn inclockw ise dire c tion).

The contro l loads the m achine program .

The startscreen appears inthe display ofthe controlpaneland

show s the follow ing m essage:

WAITING FOR RESET

–

Unlock the program stop key 2 atthe controlpanel.

3.2Switching off

–

Press program stop key 2 atthe controlpaneluntilitlocks.

–

Switch offm ainswitch1(turn counte r-c lockw ise).

6

21

3.3 Program stop

Foran im m ediatestop in case ofoperating errors,needle breakage

etc.the safety system ofthe 1265/5provides the follow ing m easures:

–

Press program stop sw itch2atthe controlpanel.

The running operations are stopped im m ediately.

–

Turn m ainswitch 1 counte r-c lockw ise.

The sewing unitdrops outim m ediately;

allm ovem entsofthe sew ing unitstop im m ediately.

3.4 R estartafterprogram stop

Caution:R isk ofinjury!

Switch the m ainswitch off.

Clearthe faultonlywiththe sew ing unitsw itched off.

Onlyrestartthe sew ing unitafterthe faulthas been cleared.

–

Switch on m ainswitch1(turn inclockw ise dire c tion).

–

Unlock the program stop sw itch.

The contro l loads the m achine program .

The m ain screen appears inthe display ofthe controlpanel.

The sewing unitis ready foroperation again.

7

1

21

2

4. O peration ofthe sew ing m achine head

4.1 G eneralnotes

The operation ofthe sew ing m achine head (needleinsertion,threading

ofneedlethread and hook thread etc.)is described inthe separately

attached Pegasus operating instru c tions.

The instru c tion m anualisincluded inthe accessories ofthe sew ing

unit.

A tte n tion:Risk ofinjury!

Please read the operating instru c tions ofthe sew ing m achine head

carefully and observe allsafetyinstru c tions.

8

4.2 R ecom m ended threads

N eedle system : B27

R ecom m ended

needlesize: N m 80 forvery thinmaterial

Nm 90forthinmaterial

N m 100 form edium -w eightm aterial

High sew ing security and good sew ability are achieved w iththe

follow ing core threads:

–

Tw o-ply polyesterendless polyestercore-spun

(e .g.E picPoly-P oly,R asantx,Saba C ,...)

–

Tw o-ply polyesterendless cotton core-spun

(e .g.Frikka,K oban,R asant,...)

Ifthese threads are notavailable,the polyesterfibre orcotton threads

listed inthe table can also be sew n.

Often two-plycorethreads are offered by the thread m anufacturers

withthe sam e designation as three-ply polyesterfibre threads

(3cyl.-spun).This causes uncertaintywith regard totwisting and thread

thickness.

W hen in doubt,unravelthe thread and check w hetheritistwisted 2-or

3-ply.

The labelno.120 on the thread reelofa core thread corresponds e.g.

tothe thread size N m 80/2(seetablevalues in brackets).

In case ofm onofilam entthreads you can use needlethreads and hook

threads ofthe sam e thickness.The bestresults are achieved w ithsoft

and elasticthreads (software)ofthe thread thickness 130 D enier.

R ecom m ended thread thicknesses:

N eedlesize C o re th re a d C o re th re a d

Nm

N eedlethread H ook thread N eedlethread H ook thread

Polyester Polyester Polyester C otton

endless core-spun endless core-spun

LabelN o. LabelN o. LabelN o. LabelN o.

80

90 120 (N m 80/2) 120 (N m 80/2) 120 (N m 80/2) 120 (N m 80/2)

100 100 (N m 65/2) 100 (N m 65/2) 100 (N m 65/2) 100 (N m 65/2)

N eedlesize P o lyester fibre thread Cotton thread

N m (3cyl.-spun)

N eedlethread H ook thread N eedlethread H ook thread

80 N m 120/3 N m 120/3Ne

B

60/3-80/3Ne

B

60/3-80/3

90 N m 80/3-120/3 N m 80/3-120/3Ne

B

50/3-70/3Ne

B

50/3-70/3

100 N m 70/3-100/3 N m 70/3-100/3Ne

B

40/3-60/3Ne

B

40/3-60/3

1

9

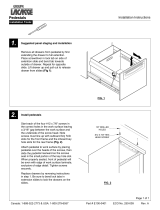

4.3Removing /Putting on the fabricsliding sheet

The fabricsliding sheet2 is heldinthe gap ofthe tabletop by the

m agnets1.

The edge guide3isfastened on the fabricsliding sheet.

Rem oving the fabricsliding sheet

–

Carefully rem ove the fabricsliding sheet2 fro m the m agnetsin

upw ard dire c tion.

–

Rem ove the fabricsliding sheet2 sidew ards.

The low ersection ofthe sew ing m achine head is accessible now .

P u tting on the fabricsliding sheet

–

Push the fabricsliding sheet2 intothe gap ofthe tabletop and

insertitin dow nw ard dire c tion.

10

23 1

23

5. O peration ofthe sew ing unit

5.1 Footsw itch m achine sequence

Insomesewing program s the footsw itch serves forstarting various

functions.

The footsw itch is equipped w ithtw o contacts.

O ne contactislocated inthe reararea and isreleased by stepping

back.

The otherone islocated inthe frontarea and isreleased by

m echanicalload.

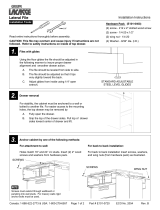

5.2 Feeding the trousers partsandstarting the sew ing operation

The overlock unit1265/5 w orks sem i-autom atically.

The operatorofthe sew ing unithas to proceed as follow s:

l callup the desired seam program

l feed the m aterialaccurately

l supervise the sew ing process

l re m o v e the finished partsfro m the stacker

Feeding the trousers partand starting the sew ing operation

1) Selectthe seam program atthe controlpanel(see chapter6.4.2).

2) Place the trousers part1 on the tabletop3fro m the rightand

position itprecisely underneaththe contourguide 2.

ATTENTION!

As soon as the trousers partis pushed underneaththe lightbarrier4,

the sew ing operation starts autom atically and the contourguide 2

low ers.

11

1

32 1

42

3) The trousers partis sew n.

4) The puller5 low ers,too,and supportsthe feeding ofthe trousers

part.

5) As soon as the m aterialhas passed the lightbarrier,the seam is

finished and the ejector6 low ers.

6) The contourguide 2 and the puller5 m ove upw ards.

7) The ejector6 transportsthe m aterialoutofthe sew ing area.

8) The stacker clam p 8 m oves tothe front.

9) The ejector6 m oves upw ards again.

10) The trousers partisstacked.

11) A ctuatefootsw itch7forrem oving the w orkpieces.

Note

In ordertofacilitatethe m aterialfeed inthe area ofthe sew ing head

the tableblow ing and the ejector6 can be engaged atthe seam

beginning.

(see chapter5.4)

12

652

87

5.3Adjusting the edge guide

The height-adjustable edge guide ensures a precise positioning ofthe

trousers partinfrontofthe sew ing head.The heightofthe edge guide

canbeadjusted depending on the thickness ofthe m aterialtobe

processed.

The draw roll4 guarantees a precise m aterialfeed underthe sew ing

foot.

Adjusting the heightofthe edge guide

–

Draw the dial1 inthe dire c tion ofarrow .

–

Setthe dial1 to one ofthe fourlock-in positions.

Position1=minim um height

Position4=maxim um height

Fine adjustm entofthe heightofthe edge guide

–

Turn the dial2 correspondingly.

S e tting the contactpressure ofthe roller 4

–

Turn the dial3 inclockw ise dire c tion.

The conta c t p re s s u re o f the rolleris reduced.

–

Turn the dial3 counte r-c lockw ise.

The conta c t p re s s u re o f the rollerisincreased.

13

1

43

1

2

5.4Adjusting the blow ing airforthe nozzles inthe tabletop

The blastnozzles 1 inthe tabletop supportthe precise stacking ofthe

workpieces.

–

Setthe intensityofthe airblastw iththe dial2 atthe controlpanel.

Turn dialtothe right = increased intensityofairblast

Turn dialtothe left = reduced intensityofairblast

14

2

1

5.5Stackers

5.5.1Standard stacker

Onthe standard stacker the finished w orkpieces are bundled.

As soon as the balance pointofthe trousers parthas been pushed

beyond the tabletop edge 2 by the ejector1,the shield4ofthe stacker

extends and presses the trousers partagainstthe frontbundle bar5.

The blow ing device1ofthe stacker blow s the trousers parton the

stackerover the tw o bundle bars 5 and 6.

The stacker isactivated by a controlpulse.The pneum aticfunctions

canbetaken fro m the pneum aticwiring diagram .

Caution:R isk ofinjury!

D o notreach intothe w orking area ofthe standard stacker during the

stacking operation.

M anualstacking

–

Press key F7 atthe controlpanel.

Astacking process is c a rried out.

15

1

F7

65 4 32 1

5.5.2 Throw -overstacker

The finished w orkpieces are stackedonthe throw -overstacker 2.

The stacked and clam ped w orkpieces can be rem oved by actuating the

footsw itch 1.

The stacker isactivated by a controlpulse.The pneum aticfunctions

canbetaken fro m the pneum aticwiring diagram .

Caution:R isk ofinjury!

D o notreach intothe w orking area ofthe throw -overstackerduring the

stacking operation.

M anualstacking

–

Press key F7 atthe controlpanel.

Astacking process is c a rried out.

Rem oving stacked parts

–

Actuatefootsw itch 1 and keep itactuated.

–

Rem ove the stacked parts.

16

F7

21

5.5.3Alternating stacker

Onthe alternating stacker the rightand leftfinished w orkpieces are

stacked separately.

Forthis purpose the table7ofthe stacker is m oved from one side to

the otherafterevery sew ing operation.

As soon as the balance pointofthe trousers parthas been pushed

beyond the tabletop edge 1 by the ejector5,the shield2ofthe stacker

extends and presses the trousers partagainstthe frontbundle bar3.

The ejector6 and the blow ing device atthe shield 2 position the

trousers partaccuratelyoverthe tw o bundle bars 3 and 4.

The stacker isactivated by a controlpulse.The pneum aticfunctions

canbetaken fro m the pneum aticwiring diagram .

Caution:R isk ofinjury!

D o notreach intothe w orking area ofthe alternating stackerduring the

stacking operation.

M anualstacking

–

Press key F7 atthe controlpanel.

Astacking process is c a rried out.

17

1

7

6543 2 1

F7

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

Beisler 1265-5 Operating Instructions Manual

- Typ

- Operating Instructions Manual

w innych językach

- English: Beisler 1265-5

- Nederlands: Beisler 1265-5

Inne dokumenty

-

Haworth e100-5300a Instrukcja obsługi

Haworth e100-5300a Instrukcja obsługi

-

Haworth e101-0401a Instrukcja obsługi

Haworth e101-0401a Instrukcja obsługi

-

Hitachi G12SR3 Handling Instructions Manual

-

Haworth e101-0720b Instrukcja obsługi

Haworth e101-0720b Instrukcja obsługi

-

Smartwares HA32S Instrukcja obsługi

-

JANOME Hello Kitty 15312 Instrukcja obsługi

-

Toshiba MQ01ABF050 Karta katalogowa

-

Bradford White 50A-15-3-103Q-AA Instrukcja instalacji

-

Toshiba DT01ABA300V Karta katalogowa

-

Bradford White E32-50S3-3L18 Instrukcja obsługi