-----

-----<

BOOK

NOB556

I

CIRCULAR

SAW

BENCH

PLEASE INSERT SERIAL

NUMBER OF MACHINE

MODIFICATIONS

ARE MADE

TO

THESE BOOKS FROM TIME

TO

TIME

AND IT IS IMPORTANT THEREFORE THAT

ONLY

THE BOOK SENT

WITH

THE MACHINE SHOULD

BE

USEDAS A WORKING MANUAL

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

------

_

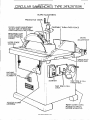

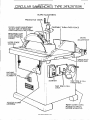

CIRCULAR

SAWBENCHES

TYPE

24'&26"BSW

RIVING KNIFE

~'"'--_-C_-:

'MCLt:

TO

SUIT SIZE

RISES

AND

FALLS

lAIn

...

MACHINE

REFERENCE

-.NUMBER

PLATE~

\SI.

......

~

-.

~~

......

CANTABLE TURN-OVER FENCE

MICRO

ADJUSTMENT

:[I~-1r-JCr:::~~::::~~GRADUATED

..

FENCE

BAR

STARTER

~\

SAW

RISE

& FALL

HANDWHEEl.

SAW

RISE

&

FALL

LOCK.

REAR

COVER

GIVES

ACCESS

TO

BELTS,

MOTOR

& PULLEYS.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

2

-------

-------------------------------------

SECTION A

SECTION B

SECTION C

SEc'nON

D

SECTION E

SECTION A

S8CTION B

SECTION C

SECTION

D

. SECTIONS

SPECIFICATION

INSTALLATION

DESCRIPTION

&

OPERATION

MAINTENANCE

SPARE

PARTS

LIST

ILLUSTRATIONS

FIG

Al

FIG

Bl

FIG

B2

FIG

Cl

FIG

C2

FIG CJ

FIG

c4

FIG

C4A

FIG

CS

FIG

C6

FIG

C7

FIG

CS-Cll

FIG

Dl

FIG

D2-DJ

FIG

D4-D12

FIG

D1J

24/26'

BSW

CDWULAR

SAWHENCHES

WDUNG

DIAGRAH

(J

PHASE)

FOUNDATION

PLAN

CANTING

FENCE

CONTROLS

FENCE

ALIGNMENT

POINTS

RIVING KNH'E

DETAIL

RISE

AND

FALL

CONTROLS

RIVING KNIFE

DETAIL

"

MITRE

FENCE

MITRE

FI!;NCE

STOP

ROJ)

POSITIONS

!

SAW

PACKINGS

OPI!;RATION

OF

OPTIONAL

FEATURES

,!

SA\{

SPINDLI!;

ASSJ!:lolllLY

DI!;LT

TENSIONING

SAW

MAINTENANCE

LUI.lIUCATION

,{

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

-,-

SPECIFICA

nON

i

Maximum

diameter

of

saw

_________________

_

Maximum saw projection

Size

of

table

Table

height

Max. distance saw to fence

Fence dimensions

Fence cants

up

to

Rise

and

fall

of

saw spindle

_________________

_

Speed

of

saw spindle

___________

~.

________

~

Horse power

of

motor

Diameter

of

saw

bore

optional

Diameter

of

driving

pin

Net

weight

Gross weight

Shipping

dimensions

.-._--

..

_----

24"

BSW

600

24/1

600mm.

9"

225mm.

43" x 34"

1090

x 860mm.

34"

865mm.

20"

500mm.

22/1

x 6"

560 x 150mm.

45"

5"

130mm.

1750 r.p.m.

7!

(optional

10)

1

&"

or

45mm.

l"

2

12mm.

1000 lb.

450 kg.

1290 lb.

590 kg.

52

eu. ft.

1.5

m'

:1

26"

BSW

650

26"

650mm.

10"

255mm.

43" x

34/1

1090 x 860mm.

34/1

865mm.

20"

500mm.

21"x

7r'

535

x 190mm.

45

5"

130mm.

1650

Lp.m.

10

If'

or

45111111.

~"

12mm.

1000 lb.

450 kg.

1290 lb.

590 kg.

52

eu. ft.

1.5 m

3

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

4

SECTION B

,

Installation:

-

I

Remove

protective

anti-rust

coating

from

bright

parts

by

'applyin~

a

cloth

soaked

in

paraffin

or

other

solvent.

Wiring:-

The

motor

and

control

gear

have

been

wired

in

before

despatch,

therefore

all

that

is

required

to

be

done

is

to

connect

the

mains

supply

to

the

starter,

or

isolator

where

fitted.

POINTS

TO

NOTE

lVHEN

CONNECTING

TO

POWER

SUPPLY.

~

-

Check

voltage,

phasA

and

frequency

2 -

It

is

important

that

the

correct

cable

is

used

to

delivAr

the

correct

voltage

to

the

starter.

RUNNING

ON

LOW

VOLTAGE

WILL

DANAGE

HOTOR.

3 -

Check

main

line

fuses

are

of

correct

capacity.

I, _

Connect

line

leads

to

correct

termin"ls

(SEE

WIRING DIAGRA}I).

5 -

Check

all

connections

are

sound.

6

Check

spindle

rotates

in

correct

direction.

If

not

reverse

any

two

of

the

line

lead

connections.

FAILURE

TO

START:-

I -

Fuses

have

blown

or

have

not

been

fitted.

2 -

Isolator

switch

ha9

not

been

closed.

J -

Lock

off

or

stop

button

(when

fitted)

has

not

been

released.

4 -

Supply

~ot

available

at

mAchl.ne.

SlOPPAGF; DUll

ING

OPBRATTON

&.

FA

lLUHE

TO

l'(ESTART:-

1 -

Ov',rloads

have

tripped.

If

i,and

re-set,

set

by

pressine:

hutton.

J f

automatJ.c

they

will

1'.'-S8L

after

a

short

period.

2.

-

FU:.ies

have

bJown.

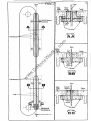

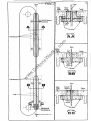

Foundation:-

The

machine

should

be

levelled'

and

bolted

down

firmly.

For

mounting

into

concrete,

6"

to

8"

square

holes

should

be

cut

in

the

floor

and

rag

bolts

fitted,

after

which

the

holes

"hould

be

run

with

cement.

For

mounting

on

wood

floors

cOBch

bolts

will

be

found

adequate.

(see

Fig.

B2.)

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

,--

-

-------------------

----

--------------------

~ROOK

RT3

STARTERCTHREE

PHASE

DIAGRAM)

,

SUP,PlY

L1

l2

LINK'

X'

BROWN

I

LlNK'T'

_I

ORANGE

\ 5

13

).

3

ab

21

33

(11)6

(13~(j5)~

~

--U---O-

c

---0-

-----0

-{P

14

~

22

14)

START

(12) 2 4 '

,6

34(16)

LINK W

REMOTE

"START.STOP"

BUTTONS

9r)

____

34t~TAR~3r5)

~6o-l

Ol.

95,(7)

O~

\--lPSTOP/RESET

BROWN

2 4 6

98.

96

(8)

(9)

(Tl)

(r2)

n)

LlNK'ZI

A B C VIOLET

"-'--..:::...--,.~~

MOTOR

5

FOR

ANY

OTHER

TYPE

OF

STARTING

SEE

SEPARATE

WIRING

DIAGRAM

ENCLOSED

INSIDE

STARTER

BOX.

FIG

BI

~

23"

(S8Smm)

0(

--

I

26~'

~

..

(666

mm)

---

----

-

--

--------

~-

--

~

-----------+-I~t

5"

4 - 8 Dia holes

FIG

B2

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

6

SECTION C

CANTING

&

RIP

FENCE

CONTROLS

.QUICK

ADJUSn!ENT:-

The

fence

slides

on

a

round

bar

with

a

rule

incorp-

orated

into

it.

To

adjust

the

fence

follow

the

under

mentioned

proceedure:-

1.

Unlock

lever

'A:

and

screw'B'(Fig.C.l.)

2.

Slide

the

fence

along

the

bar

until

the

required

dimension

is

indicated

against

the

pointer

on

the

fence

bracket.

J.

Lock

lever

'A!

firmly

to

secure

in

position.

FINE

ADJUSIMENII-

After

adjusting

the

fence

by

the

above

method

provision

is

made

for

precise

setting

by

operating

the

fine

adjust-

ment

feature.

To

operate

follow

under

mentioned

proceedure.

1.

Ensure

lever

'A'

is

UNLOCKED

and

screw'B'ia

LOCKED

firmly.(Fig.C.l.)

2.

Turn

knurled

hand

screw'C'in

direction

required

in

order

to

draw

the

fence

along

the

rule

bar

to

or

away

from

the

saw

and

to

the

required

setting.

J.

Lock

lever

'K

firmly.

CANTING:-

To

cant

fence

follow

under

mentioned

proceedure

(Fig.C.l.)

1.

Unlock

lever'D'and

allow

fence

to

pivot

over

to

required

angle.

2.

Unlock

lever'E'allowing

fence

plate

to

drop

down

until

the

lower

edge

of

the

plate

lies

flat

on

the

table

surface.

\'

",

J.

Lock

levers

D

and

E

firmly.

FENCE

POSITIONING:-

The

fence

plate

is

designed

to

slide

along

the

table

in

order

to

compensate

for

different

sizes

of

saws

which

may

be

used.

By

unlocking

lever

'E'

the

plate

maybe

s'lid

alongadovetail

slot

in

the

back

of

the

fence

to

the

required

position,

after

which

locking

lever'E'will

fix

the

fence

firmly

in

place.

NOTE:-For

crosscutting

swing

fence

over

the'

rule

bar

to

clear

the

table

FENCE SETTING

AND

ALIGNINGI-

On

despatch

from

the

works

the

movements

of

the

fence

have

been

finely

adjusted

for

accurate

cutting

by

the

provi,sion

of

the

setting

screws

at

points

F.G.H. I.

(FIG

C2).

These

adjustments

have

seperate

uses,

and

should

only

be

re-set

to

compensate

for

wear

which

may

take

place

from

constant

use.

The

seperate

uses

of

these

points

are

as

outlined

underneath:-

POINT

F&-

is

an

eccentrically

turned

centre

which

allows

the

fence

to

be

set

paralell

to

the

saw.

or

to

be

set

in

or

out

as

requ

tred.

POINT

G:-

is

s

true

centre

which

allows

slackness

to

be

removed

between

centres

F

and

G.

POINT H:-

is

a

jacking

point

which

provides

a

positive

stop

which

will

not

allow

the

fence

to

be

pulled

up

further

than

90

degrees

to

the

table

when

set

correctly.

POINT

1:-

is

also

a

jacking

point

which

brings

centres

F

and

G

parallel

to

the

table

for

true

canting

action

of

the

fence.

NOTE:-

SET

ALIGNMENT

ONLY

WITH

CENTRE

F.

DO

NOT

PACK

BETWEEN

BACK

PLATE

AND

FENCE

AS

TIllS

CAN

CRACK

THE

CASTINGS.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

--

,

7

FIG.Cl

FIGC2

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

8

RISE

AND

FALL

CONTROLS:-

By

turning

handwheel

'J'

(fig.

C4

)

the

sa"

may

be

r~ised

or

lo"ered

between

the

maximum

and

m1.nimum

position

as

given

in

section

'A'

specification.

Under.

no

circumstances

should

this

dimension

be

varied.

It

is

important

after

operatin~

the

rise

and

fall

that

lever

handle

'K'

is

locked

firmly

before

running

the

saw.

The

rise

and

fall

handwheel

is

connected

through

pivoted

yolks

at

points

A.

&

B.

(FIG

C4.)

At

the

handwheel

end

of

the

screw

a

thrust

race

C

is

fitted

to

give

free

ro·tation

"hen

in

use.

It

is

therefore

important

that

the

pivots

and

screw

are

cleaned

and

luhricated

regular-

ly

and

that

the

thrust

race

is

oiled

accordinl"

to

the

maintenance

schedule.

llIVING

KNIFE

PLATE:-

The

riving

knif"

p1~te

is

situated

behind

the

sa'"

in

the

saw

COI'1-

p~rtment

'D'

(fig.

C4A)

and

~llows

the

rivinp:

knife

to

rise

and

fall

with

the

saw

at

a

set

clearance

to

the

saw

teeth.

It

is

important

that

the

area

surrounding

the

radial

slot

cut

in

the

plate

be

kept

clean

and

\fell

lubricated

to

give

free

movement.

HIVING

KNIFE

HOLD!;;"

DETAIL

The

rivjng

knife

is

supplied

in

the

inverted

position.

fit

upright

adoptinl';

the

following

proceedure:

-(figC3)

Remove

and

1.

Fit

knife

into

grooved

pack:ln,,,:

piece

'E'

and

bolt

up

to

solid

pack-

inp:

piece

'F'

with

the

."

nuts

'G'

provided.

2.

.1"

.\

1.

'G'

has

With

saw

in

plade

set

knife

to

clear

around

sa"

teeth

approximatelY

(6mm)

and

lock

firmly

in

place

with

nuts

'G'

•

If

the

knife

is

not

in

line

with

the

saw,

partially

slacken

nuts

and

jack

packing

piece

'F'

out

,dth

p;rub

screws

'H'

until

the

knife

e~u~l

overhand

either

side

of

the

saw

blade.

Lock

nuts

'G'

firmly.

NOTE:

- BEFORE

RUNNING,

ADJUST

SAl,

GUARD TO

GIVE

t<li\XDlUH

PROTECTION

AND

TO CLEAR SA1,

BLADE.

DO

NOT RUN

HACHINE

I>ITHOUT

GTJARD

IN

POSITION.

INPOf{TANT:

-

t;NSUf{~;

THAT

RIVING

KNIFl;;

BLADE

IS

CORr{ECT

TJIICIGiESS

F(U

SA\!

VSED

j~\

®

I.

-

.~

1\1

\

E

Riving Knife

H

Plate

Riving Knife

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

-,

-

J

A

K

FIGC4

FIGC4A

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

10

HOUNTING

SAliBLAOES:-

When

mounting

saws

the

undermentioned

proceedure

shoulrl

be

fOllowed:-

1.

Isolate

machine

2.

Remove

table

insert

and

raise

the

saw

spindlp

ho"sing

into

the

top

position.

J.

Remove

spindle

nut

(left

hand

thread)

And

front

saw

flAnge

f'rom

spindle.

4.

Select

blarle

required

depending

on

type

of

work

which

is

to

be

done.

Check

the

hlade

is

in

good

condition

and

free

from

dirt.

sawdust

and

,?,Um.

especiAlly

where

it

will

he

gripped

by

the

SAW

flange.

Hount

saw

on

the

Rpindle

checking

that

the

fac~

of

the

hack

saw

flange

is

clean

And

thAt

the

saw

bore

and

pin

hole

centres

fit

correctly

onto

those

on

the

flange.

').

Check

that

the

saw

teeth

point

towards

the

front

of

the

mAchine

be-

fore

replacing

the

flange

and

locking

up

f'irmly

with

the

spindle

nut.

THPO.tTANT:

-

ENSURE

SPINDLE

il.UNS

IN

COHRECT ClIRI,;CTION, f(8Fj<.;n

TO

SrXTIlJN

..!l..

(ELECTRICS

L

NOTE:-

IF

Tlm

FL.\)IIGE

OR

SA',[

~'ACES

ARE NOT CLlCA'I

TillS

CAN

CAUSE

VIJlHATION

HUE TO THE

SAW

RUNNING

OUT-OF-TRUE.

MITHE

FENCE

(;C.1..p....Jt5)_(EXTRA.)

The

mitre

fence

is

fitted

into

the

groovp

provided

on

the

seo",

t"hle,

which

should

be

kept

clean.

A

scale

is

provirled

to

inrlicate

accurate

setting,

and

a

positive

stop

'A'

is

incorporaterl

in

the

seale

to

give

quick

setting

at

90

0

and

45

0

to

the

saw.

The

plastic

hAnd'"heel

'B'

locks

the

mitre

fence

firmly

in

any

position.

Accurate

repetitive

cutting

can

be

ohtAined

by

USA

of

the

stop

rods

(!'iI':.

CS.)

The

rods

are

held

in

the

fence

with

the

thumbscrews

'C'

and

the

stop

rods

hy

the

two

clamps

'D!

To

adjust

the

stop

ro<ls

slAcken

C1A"'PS

'C'

~nd

'0'

anrl

slide

the

rorls

into

the

position

req'Jired

~s

illustrHted

in

(fig.

C6.)

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

MITRE

SLOT

STOP

RODS

C

~'----'.

----.

-

-

~

FIGC5

I1

I

!

FIGC6

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

12

SAli

PACKING.

It

is

usual

to

provioe

a

sa'"

blade

with

some

form

of

packing,

but

it

is

not

intenoed

th"t

this

packing

be

used

as

"

R"uioe

for

buckleo

or

out-of-true

saws.

The

idea

of

fitting

pi-.ckinp,'

piecAs

into

the

table

and

gap

plate

is

to

steady

the

saw,

but

it

should

he

noted

that

the

packing

must

not

be

tight

"s

this

"ill

generate

heat,

resulting

in

a

consequent

loss

of

tension

in

the

blaoe.

The

arrangement

of'

the

saw

packing's

are

in

such

a

way

thRt

"

hard-

wood

mouthpiece

of'

a

length

extending

beyono

the

depth

of

the

saw

teeth

retains

the

f'elt

packinl':

pieces

in

place.

Also

wood

strips

secured

to

the

underside

of'

the

tRhle

and

to

the

front

of'

the

Il'ap

plate

support

the

f'elt

in

position.

At

the

rear

of

thA

g"p

plAte

anrl

table

si.milar

wood

strips

close

the

saw

p;ap

and

provide

a

p;uioe

for

the

saw.

(SEE

nIAGHilHS

OPPOSITE.

)

It

shoulrl

he

noted

thnt

after

some

time,

the

packinll's

will

need

to

he

rene"eo,

ano

sho111(1

not

he

"110,,eo

to

fall

into

b"o

conrlition.

The

rrovision

of'

the

felt

inserts

allow

application

of'

a

s",,,11

amount

of'

lubricating

oil,

which

not

only

cleans

the

saw,

hut

"Iso

re-

ouces

heat

and

burning

whilst

runninp,'.

It

is

therefore

important

that,

at

every

opportunity,

the

felt

pieces

are

1uhricaterl.

NOTE:-

REPLACENENT LENGTHS OF

FELT

l'~7/'l6"

x

6"

.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

I

Saw

~

-cr-

1---

I(~"'"

I

I

~L

I

I

I

I

I

I

lEE>

L_

~--

I

----,

I

C)("~e=====:::::::=t==+~:f-.II

Hardw{)j

I

I

a:(B

®:a'

LL-I-4~.~

I I

I

I I

Felt·~+======t=l~~

:

I

I

EBI

.F

FIGC7

--17/Ndl.._I~ardwood

- - mouthpiece

Gap

plate

Saw

SECTION

~A

Saw

Felt

Table

Screw

SECTION

~aa~

Saw

13

Gap Mouth

plate piece

...

:

...

::+

",

/

/h/

X

-

I

/

" / 11-

"-

Table

""...,....,..,.,.'-.r

l

.-.

'1.""

J<

/

If

--1,/

,/

/ I

'i1

I

,"

SECTION~

~CC

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

14.

B

FIG

CB

PILLAIl

SAW

GUARD

To

re

ise

and

lower

the

gua

rd,

unlock

lever

'A'

anrl

turn

hanrlle

'B'

(FIG

CB)

To

position

the

guard

on

centre

witll

the

saw,

unlock

lever

'C'

anrl

slirle

the

guard

pillar

'0'

until

th"

guard

is

in

th"

correct

position.

To

centralize

the

guard

to

clear

saw

and

riving

knit'e,

unlock

lever

'E'

and

slide

guard

back

or

forwarc1

aJong

bar

'F'

until

correctly

positioned.

I.hen

operating,

ensure

visor

'G'

is

set

to

clear

timber

by

approximately

in

(Jmm)

To

gain

access

to

saw,

the

guard

cover

will

hinge

up

and

over

to

reve"l

blade.

FIG

C

11

SPINOLE BRAKE:-

This

device

is

operated

from

the

brake

lever

'A'

situated

next

to

the

rise

and

fall

handwheel.

It

is

connected

to

the

brake

pad

by

means

ot'

a

cable

'B'

leading

from

the

operating

lever,

and

is

spring-loaded

to

relieve

tension

",hen

hand

pressure

is

reljeved.

To

tension

the

cable,

turn

the

knurled

nut

'C'

on

the

lever.

Where

excessive

slackness

is

to

be

removed,

unlock

the

grub

screw

'D'

on

the

pillar

at

the

spindle

end

and

pull

cable

through,

re-lock

grub

screw

.md

tensionccable

as

mentioned

above

with

knurled

screw.

l¥hen

re-

placing

brake

pad

it

is

important

that

new

rivets

are

used

and

that

the

rivet

heads

-

are

below

the

surface

of

the

pad

material.

Do

not

a

llow

brake

pad

to

wear

down

to

rivets

as

this

will

score

the

surt'ace

of

the

special

pulley.(FIGC11)

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

15.

SECTION

"c"

MAINTENANCE

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

16

SECTION

D.

-

HAINTENANCE:-

During

the

operating

life

of

the

sawbench

it

may

be

fO\ln<1

necessary

to

replace

worn

or

damaged'pnrts

(i.e.

ba,ll

races.)

To

un<1ertake

this

proceedure

follow

the

undermention<~d

instr\lctions.

(SEE

FIG

D

1.)

1.

ISOLATF:

?-lAClllNE

ELECTRICALLY

BEFOaE

ATTENPTING

ANY

WORK.

2.

REHOVE G<\P

PLATE,

SAl,

AND

SA1~

SPDlDLE

FRONT

AN·)

H~;AH

COVERS FRON

1'111':

).

4.

5.

6.

8.

'.'.

10.

MACHINE.

SLACKEN AN]) RBHOVE

V-ROPES

FRON

PULLEYS

1\]\1)

HF:~IOVE

TURNnUCKLB

AND

TENSION

STUDS

.\FTER

PAC1CING HOTOR UT'

,\S

SH01{N

IN

(FIG

D.2.)

WIND SAIl'

CARRIAGE

INTO

HIDWAY

POSITION.

REMOVE COUNTERSUNK SCRE1; ANI)

I,ASHSR

'A

t

AND

SLACKEN GRUB SCRE1,rS

'H'

IN

PULLEY

'C'

AND

RENOVE.

RE}iOYE KEY

'D'

AND

DISTANCE

PIF:CE

'E'.

RENOVB

CIRCLIP

'F'

AND

HOTOH

T8NSION

HRACKgT

'G'

ANIl lJNSCHE1,

AND

HEHO

YE

DUSTCAP

'H'.

WORKING

AT

T!lE

FRONT

OF

THg

SAW

SPINDU~t

HENClVE NUT

'I'

(L.H.THHEAD)

AND

SA

IV

FLANGE

'J'.

UNSCfmw

SAt,

FLANGE

'K'

(L.Jl.Tl{Hr;AD.)

HEHClVE

RIVING

KNIFE

PLATE*ANl)

LINK,

AND

UNSCHEW

A~,1l

im)'IOVE

nUST

CAP

t

L'

•

11.

PLACE

A I{oODEN

DRIFT

ON

THE

PULU;Y

EN])

OF

TlIE

SPI:-iDU:

ANIl

f)[(IVE

'I'll"

SHA~'T

THROUGH

Tlm

HOIJSING.

TIY

D01NG

TlIIS

TilE

Sf'INi)LE

\HLL

!';hEHGE

FRO}!

THE

HOPSING

\HTIl

TIlE

SA"

EN')

R8AIUNG

ON

IT.

T)llIVE

THIS

BEAR-

ING

FHON

TilE

SHAFT

AND

RE-INSEaT

SHAFT

INTO

HOrSING

KNUCl:ING

SPINDU:

TITH.OTlGIl

'HTH

HA}IHER

ANT)

mUI'''!'

TO

IlENOvg

THB

PllLLSY

EW)

nEAHING

•

..

To

re-assemble,

reverse

above

proceedure

eneurinr:

all

orie;inal

pFtrts

A

re

thoroughly

cleanerl

out.

*"

It

shoul<1

a.1so

be

note<1

thAt

the·,

two

locknuts

on

thp.

radi"l

slot

in

th

e

ri

vi

nIT

kni

f'e

pla

te

should

only

be

t

iroh

t

enprl

pnour:;h

to

provirle

a

flU

id

e

for

the

motion

of

the

plate

"nrl

not

to

clamp

or

lock

the

plate

in

po"i-

tion.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

17

'1

GJ

o

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

18

--------~~-----------

BELT

TENSION:-

On

all

mAchines

the

drive

from

the

main

motorto

the

saw

spindle

is

by

means

of'

four

ALPHA

500,

type

"V"

Belts.

To

ensure

maximum

efficiency

and

life.of

these

helts,

it

is

important

that

the

correct

belt

tension

is

maintained

at

all

times

from

new,

especially

in

the

"running

in"

period.

To

tension

the

belts

follow

the

undermen-

tioned

proceedure.

(SEE

FIG.

D.2.)

By

turning

turnbllckle

'A'

linking

the

tension

studs,

the

centre

distance

of

the

pullevs

can

be

increased

to

provide

greater

tension

on

the

belts.

To

achieve

the

correct

tension,

measure

the

centre

distance

of

the

pulleys

(FIG

DJ.)

and

adjust

with

the

turnbuckle

until,

whilst

applying

a

force

at

right

angles

and

central

Along

the

belt,

the

deflec-

tion

is

not

greater

than

1/64"

per

inch

of

span

-

(e.g.

2J"

span

=

2'3/6h"

defle

ct

ion.)

REPLACING

BELTS:-

To

replace

belts,

decrease

pulley

centre

distance

by

screwing

buckle

and

thll"

relievi.ng

tension

on

the

belts

for

their

removal.

wards

retension

as

given

above.

POINTS

TO

NOTE

WHEN

HAINTAINING

BELT

DRIVES:-

1.

2.

J.

4.

ALWA

YS

HAINTAIN

COimECT

BELT

TENSION.

REPLACE

\VOIt"

BELTS

WITH SAl'lE

TYPE

AS

SPECIFIED.

ALtrAYS RF:PLACE

11'OHN

OH

D.\HAGED BELTS

IHHEDIATELY.

ENSURE

PUlLEYS

ARE CORl{ECTLY

ALIGl\ED.

turn-

Aft

er-

5.

DO

NOT

PRISE

BELTS OVER

PULU~YS

\HTH

SCHEl,

DRIVERS

OR OTHER SHARP

IMPLEHENTS

AS

THIS

CA?

DAMAGE

BF;LTS.

6.

,

ENSFRE

PULLEY GHOOVES

AND

BELTS

AHE

CLE:AN

AND

REMOVE

ANY

OIL,

GREASl')

RUST

OR

BURRS 1.11lCIl ARE

PHES~~NT.

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Method of packing up

motor for removal of

tension screws as

outlined in sectionDl

I

19

~--+--t---A

FORCE

FIG

D2

FIG

D3

DEFLECTION

1f640F

AN

INCH

PER

INCH

OFSPAN

www.DaltonsWadkin.com

www.DaltonsWadkin.com

www.DaltonsWadkin.com

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

Wadkin 24BSW Instrukcja obsługi

- Typ

- Instrukcja obsługi

- Niniejsza instrukcja jest również odpowiednia dla

w innych językach

- English: Wadkin 24BSW User manual

Inne dokumenty

-

Luna BCS 250P Original Instructions Manual

-

Scheppach HM100T Original Operating Manual

-

Makita LF1000 Instrukcja obsługi

-

Makita LH1040 Instrukcja obsługi

-

Festool CS 70 EBG-Set Instrukcja obsługi

-

Festool PRECISIO CS 70 EB Instrukcja obsługi

-

Festool CS 50 EBG Instrukcja obsługi

-

Festool CS 50 EBG Instrukcja obsługi

-

Parkside PHKS 1300 A1 Operation and Safety Notes

-

Kompernass Saw PHKS 1450 LASER Instrukcja obsługi