1

PL INSTRUKCJA ORYGINALNA (OBSŁUGI) ............................................ 2

EN TRANSLATION (USER) MANUAL ..................................................... 3

RU РУКОВОДСТВО ПО ПЕРЕВОДУ (ПОЛЬЗОВАТЕЛЯ) ....................... 5

HU FORDÍTÁSI (FELHASZNÁLÓI) ÚTMUTATÓ ...................................... 7

RO MANUAL DE TRADUCERE (UTILIZATOR) ........................................ 8

SK PRÍRUČKA NA PREKLAD (POUŽÍVATEĽ) ........................................ 10

2

PL

INSTRUKCJA ORYGINALNA (OBSŁUGI)

PODNOŚNIK HYDRAULICZNY 11-730

UWAGA: PRZED PRZYSTĄPIENIEM DO UŻYTKOWANIA

NARZĘDZIA NALEŻY UWAŻNIE PRZECZYTAĆ NINIEJSZĄ

INSTRUKCJĘ I ZACHOWAĆ JĄ DO DALSZEGO

WYKORZYSTANIA.

Instrukcja stanowi zbiór niezbędnych informacji, ostrzeżeń,

wskazówek, opisów działania i zasad konserwacji i obsługi. Zaleca się

przechowywać instrukcję łącznie z gwarancją i fakturą lub rachunkiem

uzyskanym przy zakupie.

UWAGA: Podnośnik służy do pracy wewnątrz pomieszczeń.

„Produkt może się nieznacznie różnić w odniesieniu do zdjęć i opisów

zawartych w instrukcji”.

Mimo zastosowania konstrukcji bezpiecznej z samego założenia,

stosowania środków zabezpieczających i dodatkowych środków

ochronnych, zawsze istnieje ryzyko szczątkowe doznania urazów

podczas pracy.

• Czas życia podnośnika to 10 000 operacji. Nie należy używać

podnośnika po czasie życia określonym przez producenta.

• Podnośnik nie jest przeznaczony do podnoszenia osób, takie

działania są zabronione.

• W czasie korzystania z podnośnika użytkownik jest zobowiązany do

obserwowania urządzenia oraz ładunku w czasie podnoszenia.

• W czasie napełniania lub uzupełniania układu hydraulicznego, należy

bezwzględnie stosować płyn zalecany przez producenta

• W czasie eksploatacji urządzenia należy zwracać uwagę na

wszystkie oznaczenia znajdujące się na podnośniku. Należy zadbać,

aby zawsze były widoczne oraz czytelne.

• Do podnośników zalecamy używać oleju hydraulicznego HVI 13

• Narzędzia nie należy używać w atmosferze wybuchowej.

• Istnieje niebezpieczeństwo doznania obrażeń w przypadku

trzymania rąk w pobliżu punktu podparcia podnośnika, szczególnie

przy podnoszeniu i opuszczaniu ciężaru.

• Nie zbliżać rąk podczas pracy w pobliże podpory.

• Istnieje zagrożenie osób przez niekontrolowany opad podniesionej

masy w przypadku uszkodzenia podnośnika. Podnośnika można

używać jedynie na płaskiej i twardej powierzchni zorientowanej w

poziomie.

• Upewnić się, czy podnośnik jest pewnie ustawiony.

• Upewnić się, że masa podnoszona jest mniejsza od maksymalnego

udźwigu podnośnika

• Na miejscu pracy należy utrzymywać porządek i zapewnić dobre

oświetlenie. Nieporządek i złe oświetlenie przyczyniają się do

wypadków.

• Zwracać uwagę na warunki panujące w miejscu pracy. Nie wolno

wystawiać podnośnika na działanie wilgoci.

• Należy zabezpieczyć miejsce pracy przed osobami postronnymi a

szczególności dziećmi. Należy zwrócić uwagę i nie dopuszczać dzieci

ani osób postronnych do miejsca pracy.

• W czasie pracy podnośnikiem należy być skoncentrowanym,

rozproszenie uwagi może spowodować utratę kontroli nad

podnośnikiem.

• Nieużywany podnośnik należy przechowywać poza zasięgiem

dzieci.

• Nie należy udostępniać podnośnika osobom niezaznajomionym z

nim lub które nie przeczytały niniejszej instrukcji obsługi, podnośnik

może być niebezpieczny w rękach nieprzeszkolonych użytkowników.

• Nie wolno stosować podnośnika do celów, dla których nie jest on

przeznaczony.

• Należy stosować środki ochrony osobistej, okulary ochronne i

rękawice ochronne. Używanie osobistych środków ochronnych takich

jak: obuwie antypoślizgowe, kask ochronny, środki ochrony słuchu (w

zależności od rodzaju zastosowanego narzędzia) – zmniejsza ryzyko

obrażeń.

• Należy cały czas utrzymywać pewną postawę, zachowując

równowagę. Umożliwi to lepszą kontrolę nad podnośnikiem w

nieprzewidzianych sytuacjach.

• Regularnie kontrolować stan oleju hydraulicznego i w razie potrzeby

uzupełnić brak a przepracowany olej wymienić. Dźwignię podnośnika

należy zawsze utrzymywać w czystości, sucha, bez śladów oleju lub

smaru gwarantuje pewny uchwyt. Podczas pracy podnośnikiem

należy być przewidującym i zachować ostrożność podczas

wykonywania każdej czynności. Nie należy pracować podnośnikiem,

gdy jest się zmęczonym lub pod wpływem narkotyków lub alkoholu.

Chwila nieuwagi podczas pracy może spowodować poważne

obrażenia ciała.

• Przed podjęciem pracy sprawdzić stan techniczny podnośnika,

zamocowanie elementów i czy nie ma widocznych pęknięć. Nie wolno

pracować podnośnikiem, w którym niewłaściwie działa pompa

hydrauliczna.

• Naprawę podnośnika należy zlecać wyłącznie osobie

wykwalifikowanej, wykorzystując wyłącznie części zamienne, dzięki

temu będzie dalej bezpieczne w użytkowaniu.

Ostrzeżenie: Podnośnik służy wyłącznie do podnoszenia.

Powierzchnia, na której należy podnośnik umieścić powinna być

płaska, twarda i zorientowana w poziomie. Przed rozpoczęciem

podnoszenia np. pojazdu należy zablokować koła podstawiając kliny i

użyć hamulec postojowy. Zabrania się prac pod pojazdem lub innym

przedmiotem spoczywającym na podnośniku. Bezwzględnie

podniesiony przedmiot (pojazd), zabezpieczyć za pomocą

dodatkowych podpór stałych na których bezpiecznie może spocząć

cały ciężar. Przed przystąpieniem do podnoszenia upewnij się, że

podnośnik jest w dobrym stanie technicznym. Nie wolno dokonywać

jakichkolwiek regulacji zaworu bezpieczeństwa.

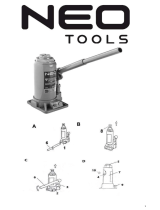

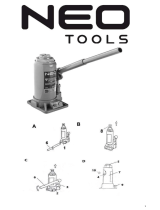

ELEMENTY PODNOŚNIKA

1. Podpora

2. Dźwignia podnośnika

3. Blokada dźwigni

4. Zawór upustowy

5. Zawór bezpieczeństwa (występuje tylko w niektórych

modelach podnośnika)

6. Gniazdo dźwigni

7. Korek wlewu oleju

8. Gniazdo smarowania sworznia (występuje tylko w niektórych

modelach podnośnika)

UWAGA! Nie wolno przystępować do pracy pod pojazdem

podpartym na podnośniku.

Nie wolno rozbierać podnośnika, może to doprowadzić do

wadliwego działania lub uszkodzenia podnośnika co może

skutkować ryzykiem utraty zdrowia lub życia.

PRZYGOTOWANIE DO PRACY

Połączyć ze sobą dwie części dźwigni, złożoną dźwignię umieścić w

gnieździe dźwigni i zabezpieczyć blokadą dźwigni wkręcając blokadę.

PODNOSZENIE:

Zamknąć zawór upustowy, obracając dźwignią w prawo.

Zabezpieczyć pojazd przed przemieszczaniem. Umieść podnośnik

pod pojazdem, w stosownym miejscu (sięgnij po informację do

Instrukcji Użytkowania, właściwej dla danego pojazdu). Wykonując

ruchy w górę i w dół pompuj dźwignią, aż do podniesienia pojazdu na

pożądaną wysokość.

OPUSZCZANIE:

3

Pokręcając dźwignią, otworzyć zawór upustowy (aby tego dokonać

trzeba POWOLI obracać dźwignię w lewo).

OSTRZEŻENIE! DŹWIGNIĄ OBRACAĆ POWOLI! POJAZD

NALEŻY OPUSZCZAĆ POWOLI! NIE WOLNO WYKONAĆ WIĘCJ

NIŻ JEDEN PEŁNY OBRÓT.

Po zakończeniu opuszczania, usunąć podnośnik spod pojazdu.

OBSŁUGA I KONSERWACJA

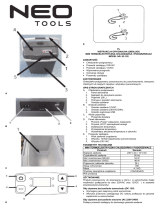

NAPEŁNIANIE OLEJEM HYDRAULICZNYM (Rys. 4):

Postawić podnośnik w ustawieniu pionowym. Przesunąć tłok pumpy

w skrajne dolne położenie. Wyjąć gumową zaślepkę z cylindra

podnośnika.

Napełnić podnośnik olejem hydraulicznym. (Należy napełniać olejem

do dolnej krawędzi otworu wlewowego.) Usuń powietrze z podnośnika

w sposób opisany poniżej (w punkcie „Usuwanie powietrza z układu

hydraulicznego”).

Zamontować zaślepkę na powrót do cylindra podnośnika.

USUWANIE POWIETRZA Z UKŁADU HYDRAULICZNEGO

(ODPOWIETRZANIE)

W układzie hydraulicznym gromadzi się powietrze, co powoduje

spadek skuteczności działania podnośnika. W tym celu należy usunąć

powietrze z układu hydraulicznego, postępując w sposób podany

poniżej:

Otworzyć zawór upustowy,

Wyjąć zaślepkę z otworu w cylindrze podnośnika.

Kilka razy energicznie podpompować dźwignią, aby usunąć powietrze.

Zamknąć zawór upustowy.

Zamontować zaślepkę na powrót w otwór w cylindrze podnośnika.

Po odpowietrzeniu podnośnik powinien działać w sposób prawidłowy.

Jeśli tak nie będzie, należy powtarzać procedurę odpowietrzania, aż

do skutku.

ZAPOBIEGANIE KOROZJI

Unikać kontaktu podnośnika z wilgocią. Jeśli już dojdzie do kontaktu z

wilgocią, to należy wytrzeć podnośnik do sucha i przesmarować

olejem wszystkie widoczne elementy podnośnika.

Połączenia sworzniowe i śrubę podpory podnośnika należy okresowo

smarować.

PROBLEM

PRZYCZYNA

Podn

ośnik

nie

osiąg

a

udźwi

gu

nomin

alneg

o

Podn

ośnik

opada

pod

obciąż

eniem

Wycie

k oleju

spod

zaślep

ki

otwor

u

wlewo

wego

Pom

pa

nie

staw

ia

opor

u

Pod

obciąże

niem

dźwigni

a

podnosi

się i

opuszc

za

Podnoś

nik nie

wysuwa

się na

pełną

wysoko

ść

X

X

Zawór upustowy nie jest zamknięty

całkowicie.

X

X

X

Zbyt mała ilość oleju w podnośniku.

Wymontować korek z otworu

wlewowego i dolać czystego oleju

hydraulicznego.

X

Zbiornik jest przepełniony. Wyjąć

korek z otworu wlewowego i spuść

nadmiar oleju.

X

X

X

Powietrze znajduje się w układzie

podnośnika. Otworzyć zawór

upustowy i podpompować

kilkakrotnie dźwignią podnośnika.

Zamknąć zawór upustowy.

Postępowanie powtórzyć, jeśli

zachodzi taka potrzeba.

X

X

X

Zawory nie dają się zamknąć

wskutek obecności obcego ciała.

Należy przepłukać zawory. Opuścić

tłoczysko i zamknąć zawór

upustowy. Ręcznie wyciągnąć

tłoczysko na kilkanaście

centymetrów. Otworzyć zawór

upustowy i następnie, energicznie

wcisnąć tłoczysko do położenia

dolnego.

DANE TECHNICZNE

Numer katalogowy

11-730

Udźwig statyczny [t]

1,5

Wysokość minimalna [mm]

85

Wysokość maksymalna [mm]

355

Masa [kg]

15,3

OCHRONA ŚRODOWISKA

Produktu nie należy wyrzucać wraz z domowymi odpadkami, lecz oddać

je do utylizacji w odpowiednich zakładach. Produkt nie poddany

recyklingowi stanowi potencjalne zagrożenie dla środowiska i zdrowia

ludzi.

„Grupa Topex Spółka z ograniczoną odpowiedzialnością” Spółka komandytowa z

siedzibą w Warszawie, ul. Pograniczna 2/4 (dalej: „Grupa Topex”) informuje, iż

wszelkie prawa autorskie do treści niniejszej instrukcji (dalej: „Instrukcja”), w tym m.in.

jej tekstu, zamieszczonych fotografii, schematów, rysunków, a także jej kompozycji,

należą wyłącznie do Grupy Topex i podlegają ochronie prawnej zgodnie z ustawą z

dnia 4 lutego 1994 roku, o prawie autorskim i prawach pokrewnych (tj. Dz. U. 2006

Nr 90 Poz. 631 z późn. zm.). Kopiowanie, przetwarzanie, publikowanie,

modyfikowanie w celach komercyjnych całości Instrukcji jak i poszczególnych jej

elementów, bez zgody Grupy Topex wyrażonej na piśmie, jest surowo zabronione i

może spowodować pociągnięcie do odpowiedzialności cywilnej i karnej.

GWARANCJA I SERWIS

Serwis Centralny GTX Service Sp. z o.o. Sp.k.

ul. Pograniczna 2/4 tel. +48 22 364 53 50 02-285 Warszawa e-mail

bok@gtxservice.com

Sieć Punktów Serwisowych do napraw gwarancyjnych i

pogwarancyjnych dostępna na platformie internetowej gtxservice.pl

Zeskanuj QR kod i wejdź na gtxservice.pl

Deklaracja zgodności WE

Producent: Grupa Topex Sp. Z o.o. Sp.k., ul. Pograniczna 2/4 02-

285 Warszawa

Wyrób: Podnośnik hydrauliczny

Model: 11-730

Nazwa handlowa: NEO TOOLS

Numer seryjny: 00001 ÷ 99999

Niniejsza deklaracja zgodności wydana zostaje na wyłączną

odpowiedzialność producenta.

Opisany wyżej wyrób jest zgodny z następującymi dokumentami:

Dyrektywa Maszynowa 2006/42/WE

Oraz spełnia wymagania norm:

EN 1494:2000/A1:2008

Deklaracja ta odnosi się wyłącznie do maszyny w stanie, w jakim została

wprowadzona do obrotu i nie obejmuje części składowych

dodanych przez użytkownika końcowego lub przeprowadzonych przez niego

późniejszych działań.

Nazwisko i adres osoby mającej miejsce zamieszkania lub siedzibę w UE

upoważnionej do przygotowania dokumentacji technicznej:

Podpisano w imieniu:

Grupa Topex Sp. Z o.o. Sp.k.

Ul. Pograniczna 2/4

02-285 Warszawa

Paweł Kowalski

Pełnomocnik ds. jakości firmy GRUPA TOPEX

Warszawa, 2022-05-12

EN

TRANSLATION (USER) MANUAL

HYDRAULIC LIFT 11-730

NOTE: BEFORE USING THE TOOL, PLEASE READ THIS

MANUAL CAREFULLY AND SAVE IT FOR FURTHER USE.

4

The manual is a collection of necessary information, warnings, tips,

descriptions of operation and rules of maintenance and operation. It is

recommended to store the instruction together with the warranty and

the invoice or bill obtained at the time of purchase.

NOTE: The lift is used for indoor use.

"The product may differ slightly with regard to the pictures and

descriptions contained in the manual."

Despite the use of a design that is safe by design, the use of protective

measures and additional protective measures, there is always a risk of

residual injuries during operation.

• The life span of the lift is 10,000 operations. Do not use the lift after

the lifetime specified by the manufacturer.

• The jack is not designed to lift people, such actions are prohibited.

• When using the lift, the user is obliged to observe the device and the

load during lifting.

• When filling or refilling the hydraulic system, it is imperative to use the

fluid recommended by the manufacturer

• During the operation of the device, pay attention to all markings on

the lift. Care should be taken to ensure that they are always visible and

legible.

• For lifts we recommend using HVI 13 hydraulic oil

• The tool should not be used in an explosive atmosphere.

• There is a risk of injury if you keep your hands near the support point

of the lift, especially when lifting and lowering the weight.

• Do not bring your hands close to the support when working.

• There is a danger to people by uncontrolled precipitation of the raised

mass in case of damage to the lift. The lift can only be used on a flat

and hard horizontally oriented surface.

• Make sure the lift is securely positioned.

• Ensure that the lifting weight is less than the maximum lifting capacity

of the lift

• Keep the workplace tidy and provide good lighting. Disorder and poor

lighting contribute to accidents.

• Pay attention to the conditions in the workplace. Do not expose the

lift to moisture.

• The workplace should be protected from outsiders, especially

children. Attention should be paid and children and bystanders should

not be allowed into the workplace.

• When working with the lift, you should be focused, distraction may

cause you to lose control over the lift.

• Unused lift should be kept out of reach of children.

• Do not share the lift with people who are not familiar with it or who

have not read this instruction manual, the lift may be dangerous in the

hands of untrained users.

• Do not use the lift for purposes for which it is not intended.

• Wear personal protective equipment, safety goggles and gloves. The

use of personal protective equipment such as: anti-slip footwear,

protective helmet, hearing protection (depending on the type of tool

used) – reduces the risk of injury.

• You should maintain a certain posture at all times, while maintaining

balance. This will allow better control over the lift in unforeseen

situations.

• Regularly check the condition of the hydraulic oil and, if necessary,

make up for the lack and replace the used oil. The lift lever should

always be kept clean, dry, without traces of oil or grease guarantees a

secure handle. When working with a jack, you should be foresighted

and be careful when performing any activity. Do not work with a lift

when you are tired or under the influence of drugs or alcohol. A

moment of inattention during operation can cause serious injuries.

• Before starting work, check the technical condition of the lift, the

fixation of the elements and whether there are no visible cracks. It is

forbidden to work with a jack in which the hydraulic pump is

malfunctioning.

• Repair of the lift should be carried out only by a qualified person,

using only spare parts, thanks to which it will continue to be safe to

use.

Warning: The lift is for lifting purposes only. The surface on which the

lift should be placed should be flat, hard and horizontally oriented.

Before starting to lift e.g. a vehicle, the wheels should be locked by

replacing the wedges and the parking brake should be used. It is

forbidden to work under a vehicle or other object resting on a lift.

Absolutely lifted object (vehicle), secure with additional fixed supports

on which the entire weight can safely rest. Before proceeding with

lifting, make sure that the lift is in good technical condition. No

adjustment of the safety valve must be made.

LIFT COMPONENTS

1. Support

2. Lift lever

3. Lever lock

4. Bleed valve

5. Safety valve (only available on some models of the lift)

6. Lever socket

7. Oil filler cap

8. Pin lubrication socket (only available on some models of the jack)

REMARK! Do not start working under a vehicle supported on a

lift.

Do not disassemble the lift, it may lead to malfunction or damage

to the lift, which may result in the risk of loss of health or life.

PREPARATION FOR WORK

Connect the two parts of the lever together, place the folded lever in

the lever socket and secure it with a lever lock by screwing in the lock.

RAISING:

Close the bleed valve by turning the lever to the right. Protect the

vehicle from movement. Place the lift under the vehicle, in the

appropriate place (refer to the information in the Instructions for Use,

appropriate for the vehicle). When making up and down movements,

pump with a lever until the vehicle is raised to the desired height.

LEAVING:

By turning the lever, open the bleed valve (to do this you need to

SLOWLY turn the lever to the left).

WARNING! ROTATE THE LEVER SLOWLY! LEAVE THE VEHICLE

SLOWLY! NO MORE THAN ONE FULL TURN MUST BE MADE.

When you have finished lowering, remove the lift from under the

vehicle.

OPERATION AND MAINTENANCE

HYDRAULIC OIL FILLING (Fig. 4):

Place the lift vertically. Move the pump piston to the lower extreme

position. Remove the rubber cap from the lift cylinder.

Fill the lift with hydraulic oil. (Fill with oil to the bottom edge of the filler

hole.) Remove the air from the lift as described below (under

"Removing air from the hydraulic system").

Mount the cap back to the lift cylinder.

REMOVAL OF AIR FROM THE HYDRAULIC SYSTEM (VENTING)

Air accumulates in the hydraulic system, which causes a decrease in

the effectiveness of the lift. To do this, remove the air from the hydraulic

system by following the steps below:

Open the bleed valve,

Remove the cap from the hole in the jack cylinder.

Several times vigorously inflate with a lever to remove air. Close the

bleed valve.

Install the cap back into the hole in the jack cylinder.

After venting, the lift should work properly. If this is not the case, the

bleeding procedure should be repeated until it is successful.

CORROSION PREVENTION

Avoid contact of the lift with moisture. If it comes into contact with

moisture, wipe the lift dry and lubricate all visible elements of the lift

with oil.

5

The pin connections and the jack support screw should be periodically

lubricated.

PROBLEM

CAUSE

The

lift

does

not

reach

the

nomin

al

lifting

capac

ity

The lift

falls

under

load

Oil

leaka

ge

from

under

the

filler

hole

cap

The

pum

p

does

not

resis

t

Under

load,

the

lever

rises

and

lowers

The lift

does

not

extend

to full

height

X

X

The bleed valve is not completely

closed.

X

X

X

Too little oil in the lift. Remove the

cap from the filler hole and add

clean hydraulic oil.

X

The tank is overflowing. Remove

the stopper from the filler hole

and drain the excess oil.

X

X

X

The air is in the jack system.

Open the bleed valve and inflate

several times with the lift lever.

Close the bleed valve. Repeat the

procedure if necessary.

X

X

X

The valves cannot be closed due

to the presence of a foreign body.

Flush the valves. Leave the rod

and close the discharge valve.

Manually pull out the piston rod

for several centimeters. Open the

discharge valve and then,

vigorously, press the rod to the

lower position.

TECHNICAL DATA

Catalog number

11-730

Static load [t]

1,5

Minimum height [mm]

85

Maximum height [mm]

355

Weight [kg]

15,3

ENVIRONMENTAL PROTECTION

The product should not be disposed of with household waste, but should be

disposed of in appropriate facilities. A non-recycled product poses a potential

risk to the environment and human health.

"Grupa Topex Spółka z ograniczoną odpowiedzialnością" Spółka komandytowa with its

registered office in Warsaw, 2/4 Pograniczna Street (hereinafter: "Topex Group") informs

that all copyrights to the content of this instruction (hereinafter: "Instruction"), including m.in

of its text, photographs, diagrams, drawings, as well as its compositions, belong exclusively

to the Topex Group and are subject to legal protection in accordance with the Act of 4

February 1994, on copyright and related rights (i.e. Journal of Laws of 2006 No. 90 Item 631,

as amended). Copying, processing, publishing, modifying for commercial purposes the entire

Instruction as well as its individual elements, without the consent of the Topex Group

expressed in writing, is strictly prohibited and may result in civil and criminal liability.

EC Declaration of Conformity

Manufacturer: Grupa Topex Sp. Z o.o. Sp.k., ul. Pograniczna 2/4 02-

285 Warszawa

Product: Hydraulic jack

Model: 11-730

Commercial name: NEO TOOLS

Serial number: 00001 ÷ 99999

This declaration of conformity is issued under the sole responsibility

of the manufacturer.

The product listed above is in conformity with the following EU

Directives:

Machinery Directive 2006/42/EC

And fulfills requirements of the following Standards:

EN 1494:2000/A1:2008

This declaration relates exclusively to the machinery in the state in

which it was placed on the market and excludes components which

are added and/or operations carried out subsequently by the final

user.

Name and address of the person residing or established in the EU

and authorized to compile the technical file:

Signed for and on behalf of:

Grupa Topex Sp. Z o.o. Sp.k.

Ul. Pograniczna 2/4

02-285 Warszawa

Paweł Kowalski

GRUPA TOPEX Quality Agent

Warsaw, 2022-05-12

RU

РУКОВОДСТВО ПО ПЕРЕВОДУ (ПОЛЬЗОВАТЕЛЯ)

ГИДРАВЛИЧЕСКОГО ПОДЪЁМНИКА 11-730

ВНИМАНИЕ: ПОЖАЛУЙСТА, ВНИМАТЕЛЬНО ПРОЧИТАЙТЕ

ДАННОЕ РУКОВОДСТВО ПЕРЕД ИСПОЛЬЗОВАНИЕМ

УСТРОЙСТВА И СОХРАНИТЕ ЕГО ДЛЯ БУДУЩЕГО

ИСПОЛЬЗОВАНИЯ.

Руководство представляет собой сборник необходимой

информации, предупреждений, инструкций, описаний работы,

правил технического обслуживания и эксплуатации.

Рекомендуется хранить руководство вместе с гарантией и

счетом, полученным при покупке.

ВНИМАНИЕ: Подъемник предназначен для работы внутри

помещений.

«Изделие может незначительно отличаться от фотографий и

описаний, содержащихся в руководстве»

Несмотря на использование безопасной конструкции,

использование защитных средств и дополнительных защитных

средств, всегда существует остаточный риск получения травм во

время работы.

Срок службы подъемника составляет 10 000 операций. Не

используйте подъемник сверх срока службы, указанного

производителем.

• Подъемник не предназначен для подъема людей, такие

действия запрещены.

• При использовании подъемника пользователь обязан следить

за устройством и грузом во время подъема.

• При заполнении или дозаправке гидравлической системы

необходимо использовать жидкость, рекомендованную

производителем.

• При эксплуатации подъемника обращайте внимание на все

маркировки на нем. Убедитесь, что они всегда видны и читаемы.

• Для подъемников мы рекомендуем использовать

гидравлическое масло HVI 13.

• Инструмент нельзя использовать во взрывоопасной среде.

• Существует риск получения травмы, если руки находятся

вблизи точки опоры подъемника, особенно при подъеме или

опускании груза.

• Не приближайте руки во время работы к опоре.

• Существует опасность для людей из-за неконтролируемого

опадания поднятого груза в случае повреждения подъемника.

Подъемник можно использовать только на плоской и твердой

горизонтальной поверхности.

• Убедитесь, что подъемник надежно установлен.

• Убедитесь, что вес поднимаемого груза меньше максимальной

грузоподъемности подъемника.

• На рабочем месте необходимо поддерживать порядок и оно

должно быть хорошо освещено. Беспорядок и плохое освещение

могут привести к несчастным случаям.

• Обратите внимание на условия на рабочем месте. Не

подвергайте подъемник воздействию влаги.

• Необходимо обезопасить рабочее место от посторонних и, в

частности, детей. Обратите внимание и не допускайте детей или

посторонних лиц к рабочему месту.

6

• Во время работы с подъемником следует быть

сосредоточенным, отвлечение может привести к потере контроля

над подъемником.

• Храните неиспользуемый подъемник в недоступном для детей

месте.

• Не предоставляйте подъемник лицам, не знакомым с ним или

не прочитавшим данное руководство по эксплуатации, этот

подъемник может быть опасен в руках неподготовленных

пользователей.

• Не используйте подъемник для целей, для которых он не

предназначен.

• При работе необходимо использовать средства

индивидуальной защиты, защитные очки и перчатки.

Использование средств индивидуальной защиты, таких как:

нескользящая обувь, защитный шлем, средства защиты слуха (в

зависимости от типа используемого инструмента) – снижает риск

получения травм.

• Всегда держите стойкое положение, сохраняя равновесие. Это

позволит лучше контролировать подъемник в непредвиденных

ситуациях.

• Регулярно контролируйте состояние гидравлического масла и

при необходимости восполните недостаток, а отработанное

масло замените. Рычаг подъемника всегда должен быть чистым,

сухим, без следов масла или смазки, что гарантирует надежное

сцепление. При работе с подъемником следует быть

предусмотрительным и проявлять осторожность при выполнении

любого действия. Нельзя работать с подъемником, если вы

чувствуете усталость или находитесь под воздействием

наркотиков или алкоголя. Момент невнимательности во время

работы может привести к серьезным травмам.

• Перед началом работы проверьте техническое состояние

подъемника, крепление деталей и наличие видимых трещин. Не

работайте подъемником, в котором неправильно работает

гидравлический насос.

• Ремонт подъемника должен быть поручен только

квалифицированному лицу, с использованием только

оригинальных запасных частей, благодаря этому он будет по-

прежнему безопасен в использовании.

Предостережение: Подъемник предназначен только для

подъема. Поверхность, на которой будет установлен подъемник,

должна быть плоской, твердой и горизонтальной. Перед

подъемом, например, автомобиля необходимо зафиксировать

колеса, подставив клинья, и использовать стояночный тормоз.

Запрещается работать под транспортным средством или другим

предметом, опирающимся на подъемник. Полностью поднятый

предмет (транспортное средство), закрепите с помощью

дополнительных фиксированных опор, на которых безопасно

может лежать весь груз. Перед подъемом убедитесь, что

подъемник находится в хорошем рабочем состоянии. Нельзя

производить никаких регулировок предохранительного клапана.

КОМПОНЕНТЫ ПОДЪЕМНИКА

1. Опора

2. Рычаг подъемника

3. Стопорное устройство рычага

4. Выпускной клапан

5. Предохранительный клапан (есть только на некоторых

моделях подъемника)

6. Гнездо рычага

7. Крышка заливной горловины

8. Гнездо смазки шкворня (есть только на некоторых

моделях подъемника)

ВНИМАНИЕ! Не приступайте к работе под автомобилем,

поддерживаемым подъемником.

Не разбирайте подъемник, это может привести к

неисправной работе или повреждению подъемника с риском

для здоровья или жизни.

ПОДГОТОВКА К РАБОТЕ

Соедините две части рычага вместе, поместите сложенный рычаг

в гнездо рычага и закрепите замок рычага, завинтив стопорное

устройство.

ПОДЪЕМ:

Закройте выпускной клапан, повернув рычаг вправо.

Зафиксируйте автомобиль от перемещения. Установите

подъемник под автомобилем в подходящем месте (см.

Руководство по эксплуатации конкретного автомобиля).

Выполняя движения вверх и вниз качайте рычаг до тех пор, пока

автомобиль не поднимется на нужную высоту.

ОПУСКАНИЕ:

Поворотом конца рычага откройте выпускной клапан (для этого

нужно МЕДЛЕННО поворачивать рычаг влево).

ПРЕДУПРЕЖДЕНИЕ! ПОВОРАЧИВАЙТЕ РЫЧАГ МЕДЛЕННО!

АВТОМОБИЛЬ СЛЕДУЕТ ОПУСКАТЬ МЕДЛЕННО! НЕЛЬЗЯ

ВЫПОЛНЯТЬ БОЛЬШЕ, ЧЕМ ОДИН ПОЛНЫЙ ПОВОРОТ.

После завершения опускания уберите подъемник из-под

автомобиля.

ТЕХОБСЛУЖИВАНИЕ И СМАЗКА

ЗАЛИВКА ГИДРАВЛИЧЕСКОГО МАСЛА (Рис. 4):

Поставьте подъемник в вертикальное положение. Переместите

поршень насоса в крайнее нижнее положение. Снимите

резиновую заглушку с цилиндра подъемника.

Заполните подъемник гидравлическим маслом. (Залейте масло

до нижнего края заливного отверстия.) Удалите воздух из

подъемника, как описано ниже (в разделе «Удаление воздуха из

гидравлической системы»).

Вставьте заглушку в цилиндр подъемника.

УДАЛЕНИЕ ВОЗДУХА ИЗ ГИДРАВЛИЧЕСКОЙ СИСТЕМЫ

(УДАЛЕНИЕ ВОЗДУХА)

Воздух скапливается в гидравлической системе, что снижает

эффективность работы подъема. Для этого удалите воздух из

гидросистемы следующим образом:

Откройте выпускной клапан,

Выньте заглушку из отверстия в цилиндре подъемника.

Несколько раз энергично нажмите на рычаг, чтобы удалить

воздух. Закройте выпускной клапан.

Вставьте заглушку в отверстие в цилиндре подъемника.

Подъемник должен работать должным образом после удаления

воздуха. Если это не так, повторите процедуру удаления воздуха

до успешного конца.

ПРЕДОТВРАЩЕНИЕ КОРРОЗИИ

Избегайте контакта подъемника с влагой. При попадании влаги

протрите подъемник насухо и смажьте маслом все видимые

части подъемника.

Штифтовые соединения и болт опоры подъемника следует

периодически смазывать.

ПРОБЛЕМА

ПРИЧИНА

Подъ

емник

не

дости

гает

номи

нальн

ой

грузо

подъе

мност

и

Подъ

емник

опуск

ается

под

нагру

зкой

Течет

масло

из-

под

пробк

и

залив

ного

отвер

стия

Нас

ос

не

оказ

ыва

ет

сопр

отив

лен

ия

Под

нагрузк

ой

рычаг

подним

ается и

опуска

ется

Подъе

мник не

выдвиг

ается

на

полную

высот

X

X

Выпускной клапан не

полностью закрыт.

X

X

X

Слишком мало масла в

подъемнике. Выньте пробку и

добавьте чистое

гидравлическое масло.

X

Бак переполнен. Выньте

пробку из заливного отверстия

и слейте лишнее масло.

X

X

X

В системе подъемника есть

воздух. Откройте выпускной

7

клапан и несколько раз

подкачайте рычагом

подъемника. Закройте

выпускной клапан. При

необходимости повторите

процедуру.

X

X

X

Клапаны не могут быть

закрыты из-за наличия

инородного тела. Промойте

клапаны. Опустите шток

поршня и закройте выпускной

клапан. Вручную вытяните

шток поршня на несколько

сантиметров. Откройте

выпускной клапан и энергично

вожмите шток поршня в

нижнее положение.

ТЕХНИЧЕСКИЕ ДАННЫЕ

Каталожный номер

11-730

Статическая грузоподъемность [т]

1,5

Минимальная высота [мм]

85

Минимальная высота [мм]

355

Масса [кг]

15,3

ЗАЩИТА ОКРУЖАЮЩЕЙ СРЕДЫ

Изделие не следует выбрасывать вместе с бытовыми отходами,

его необходимо утилизировать в предназначенных для этого

пунктах. Неутилизированный продукт представляет собой

потенциальную опасность для окружающей среды и здоровья

человека.

«Группа Topex Общество с ограниченной ответственностью» Коммандитное

товарищество с местонахождением в Варшаве, ул. Погранична, 2/4, (далее:

«Группа Topex» информирует, что все авторские права на содержание

данной инструкции (далее: «Руководство»), в том числе, среди прочего, его

текст, фотографии, диаграммы, рисунки и его композиция принадлежат

исключительно Группе Topex и подлежат правовой защите в соответствии с

Законом об авторском праве и смежных правах от 4 февраля 1994 г. (Зак.

вестник 2006, № 90, поз. 631 с посл. изм.) Копирование, обработка,

публикация и изменение в коммерческих целях всего Руководства и его

отдельных элементов без письменного согласия Группы Topex строго

запрещено и может повлечь за собой гражданскую и уголовную

ответственность.

HU

FORDÍTÁSI (FELHASZNÁLÓI) ÚTMUTATÓ

11-730 HIDRAULIKUS EMELŐKHÖZ

MEGJEGYZÉS: A BERENDEZÉS ÜZEMELTETÉSÉNEK

MEGKEZDÉSE ELŐTT FIGYELMESEN OLVASSA EL EZT AZ

UTASÍTÁST, ÉS ŐRIZZE MEG A KÉSŐBBI HASZNÁLATRA.

Az utasítás a nélkülözhetetlen információk, figyelmeztetések,

útmutatók, működési leírás és kezelési, karbantartási szabályok

gyűjteménye. Javasoljuk, hogy őrizzék meg az utasítást a vásárlásnál

kapott számlával és jótállással együtt.

MEGJEGYZÉS: Az emelő beltéri használatra készült.

„A termék kissé eltérhet az utasításban lévő fényképektől és leírástól“.

Bár a berendezés konstrukciója eleve biztonságos, továbbá biztonsági

és kiegészítő védelmi eszközöket alkalmaztunk, mindig fennáll egy

maradék kockázat, hogy a munkavégzés közben személyi sérülés

történik.

• Az emelő élettartama 10.000 művelet. Tilos az emelőt a gyártó által

meghatározott élettartam után használni.

• Az emelő nem emberek emelésére készült, tilos az ilyen használat.

• Az emelő használata során a felhasználó köteles figyelemmel kísérni

a gépet és a felemelt terhet.

• A hidraulikus rendszer töltéséhez vagy utántöltéséhez kizárólag a

gyártó által javasolt folyadékot használja.

• A gép üzemeltetése során vegye figyelembe a rajta lévő összes

jelölést. Gondoskodjon róla, hogy azok mindig maradjanak láthatók és

olvashatók.

• Az emelőhöz javasoljuk a HVI 13 hidraulika olaj használatát.

• Ne használja robbanásveszélyes atmoszférában.

• Fennáll a testi sérülés veszélye, ha kezét az emelő alátámasztási

pontja közelében tartja, különösen teher emelése vagy leeresztés

közben.

• Üzem közben tartsa távol a kezét az alátámasztástól.

• A felemelt teher ellenőrizetlen lezuhanása az emelő meghibásodása

esetén veszélyt jelent az emberek számára. Az emelőt csak sík és

kemény, vízszintes felületen használja.

• Győződjön meg arról, hogy az emelő biztosan áll.

• Győződjön meg arról, hogy az emelt teher tömege kisebb az emelő

maximális teherbírásánál.

• A munkahelyen rendet kell tartani és jól meg kell világítani. A

rendetlenség és rossz megvilágítás balesetet okozhat.

• Figyeljen a munkahelyen uralkodó körülményekre. Ne tegye ki az

emelőt nedvesség hatásának.

• Biztosítsa a munkahelyet illetéktelenektől, különösen gyermekektől.

Ügyeljen rájuk, és ne engedje sem az illetékteleneket, sem a

gyermekeket a munkahelyre.

• Koncentráljon az emelővel végzett munkára, a figyelmetlenség a gép

feletti uralom elvesztésével járhat.

• Használaton kívül tartsa távol az emelőt a gyermekektől.

• Ne engedje át az emelőt olyan személyeknek, akik nem ismerik azt,

nem olvasták el a jelen utasítást, mivel a gép veszélyes lehet a nem

kioktatott felhasználók kezében.

• Tilos az emelőt nem a rendeltetése szerinti célokra használni.

• Viselje az egyéni védőeszközöket: védőszemüveget és

védőkesztyűt. Olyan egyéni védőeszközök használata, mint

csúszásgátló lábbeli, védősisak, hallásvédő (a használt eszköztől

függően) csökkenti a testi sérülések kockázatát.

• Egész idő alatt őrizze meg biztos testtartását és egyensúlyát. Ez

lehetővé teszi, hogy váratlan helyzetekben is megőrizze uralmát a gép

felett.

• Rendszeresen ellenőrizze a hidraulika olaj állapotát, szükség esetén

töltse utána, ha fáradt, akkor pedig cserélje le. Az emelő karját mindig

tartsa tisztán, szárazon, olaj- és kenőzsír nyomoktól mentesen, ez

garantálja annak biztos megfogását. Az emelővel való munkavégzés

során legyen előrelátó, és óvatosan végezzen minden műveletet. Tilos

munkát végeznie az emelővel, ha fáradt, továbbá alkohol vagy

kábítószer hatása alatt áll. Akár egy pillanatnyi figyelmetlenség a

munka közben súlyos személyi sérülést okozhat.

• A munka megkezdése előtt ellenőrizze az emelő műszaki állapotát,

az elemek rögzítését és azt, hogy nincsenek-e látható repedések.

Tilos a géppel dolgozni, ha a hidraulikus szivattyú nem működik

megfelelően.

• Az emelő javítását kizárólag szakképzett személyre bízza, és csak

eredeti pótalkatrészeket használjon, ennek köszönhetően használata

továbbra is biztonságos marad.

Figyelmeztetés: A gép kizárólag emelésre szolgál. Az emelőt csak

sík és kemény, vízszintes felületen helyezze el. Jármű emelésének

megkezdése előtt ékelje ki annak kerekeit, és húzza be a rögzítőféket.

Tilos az emelőn lévő jármű vagy egyéb tárgy alatt munkát végezni. A

felemelt járművet (tárgyat) feltétlenül támassza alá bakokkal, amelyek

biztonságosan megtartják az egész súlyt. Ez emelés megkezdése

előtt győződjön meg arról, hogy az emelő jó műszaki állapotban van.

Tilos bármiféle állítást végezni a biztonsági szelepen.

AZ EMELŐ ELEMEI

1. Támasz

2. Emelőkar

3. Kar reteszelése

4. Leeresztő szelep

5. Biztonsági szelep (csak az emelő egyes típusainál)

6. Kar fészke

7. Olajbetöltő sapka

8. Csapszeg kenőfészke (csak az emelő egyes típusainál)

FIGYELEM! Tilos munkát végezni az emelővel alátámasztott

jármű alatt.

8

Tilos szétszedni az emelőt, ez hibás működéshez vagy a gép

sérüléséhez vezethet, ami az egészséget vagy az életet is

veszélyeztetheti.

ELŐKÉSZÍTÉS HASZNÁLATRA

Illessze össze az emelőkar két részét, majd illessze be a fészekbe, és

rögzítse azt a retesz becsavarásával.

EMELÉS:

Zárja el a leeresztő szelepet, ehhez forgassa el jobbra az emelőkart.

Biztosítsa a járművet elmozdulás ellen. Helyezze be az emelőt a jármű

alá, a megfelelő helyre (ezt az adott jármű felhasználói utasítása

tartalmazza). Az emelő kart le-fel mozgatva emelje fel a járművet a

kívánt magasságba.

LEENGEDÉS:

A kar elforgatásával nyissa ki a leeresztő szelepet (ehhez LASSAN

forgassa a kart balra).

FIGYELMEZTETÉS! LASSAN FORGASSA A KART! A JÁRMŰVET

LASSAN ENGEDJE LE! TILOS EGYNÉL TÖBB TELJES

FORDULATOT VÉGEZNI.

A jármű leengedése után vegye ki alóla az emelőt.

KEZELÉS ÉS KARBANTARTÁS

FELTÖLTÉS HIDRAULIKA OLAJJAL (4. ábra):

Állítsa függőleges helyzetbe az emelőt. Tolja el a szivattyú

dugattyúját szélső alsó helyzetbe. Vegye ki az emelő hengeréből a

gumi záródugót.

Töltse fel az emelőt hidraulika olajjal. (Az olajszint érje el a

beöntőnyílás alsó szélét.) Légtelenítse az emelőt a lentebb leírt módon

(„Hidraulikus rendszer légtelenítése“ c. pontban).

Helyezze vissza a záródugót az emelő hengerébe.

HIDRAULIKUS RENDSZER LÉGTELENÍTÉSE

A hidraulikus rendszerben levegő gyűlik össze, ami lerontja annak

működési hatékonyságát. Ezért az alábbi módon légteleníti kell a

rendszert:

Nyissa ki a leeresztő szelepet,

Húzza ki a záródugót az emelő hengerén lévő furatból.

Végezzen az emelőkarral néhány energikus pumpálást, hogy

eltávolítsa a levegőt. Zárja el a leeresztő szelepet.

Helyezze vissza a záródugót az emelő hengerén lévő furatba.

Légtelenítés után az emelőnek megfelelően kell működnie. Ha

mégsem, akkor addig kell ismételni a légtelenítést, amíg nem lesz

megfelelő a működés.

KORRÓZIÓ MEGELŐZÉSE

Ne tegye ki az emelőt nedvesség hatásának. Ha ez mégis

bekövetkezik, akkor törölje szárazra az emelőt, és kenje át olajjal

minden látható elemét.

A csapszeges kötéseket és a támaszcsavart időnként meg kell kenni.

PROBLÉMA

OK

Az

emelő

nem

éri el

névle

ges

teherb

írását.

Az

emelő

lesülly

ed a

teher

alatt.

Olajsz

ivárgá

s a

beönt

őnyílá

s

záród

ugója

alól

A

sziv

attyú

ellen

állás

nélk

ül

moz

og

Terhelé

s alatt a

kar

felemel

kedik és

lesüllye

d

Az

emelő

nem

tolódik

ki a

teljes

magass

ágra

X

X

A leeresztő szelep nincs teljesen

elzárva.

X

X

X

Túl kevés az olaj az emelőben.

Vegye ki a beöntőnyílásból a

záródugót, és öntsön be tiszta

hidraulika olajat.

X

A tartály túl van töltve. Vegye ki a

beöntőnyílásból a záródugót, és

engedje le az olajfelesleget.

X

X

X

Levegős az emelő rendszere.

Nyissa ki a leeresztő szelepet, és

néhányszor pumpáljon rá az

emelőkarral. Zárja el a leeresztő

szelepet. Szükség esetén

ismételje meg az eljárást.

X

X

X

A szelepek elzárását idegen test

akadályozza. Öblítse át a

szelepeket. Engedje le a

dugattyúrudat, és zárja el a

leeresztő szelepet. Kézzel húzza

ki 10-20 cm-re a dugattyúrudat.

Nyissa ki a leeresztő szelepet,

majd energikusan nyomja le alsó

helyzetébe a dugattyúrudat.

MŰSZAKI ADATOK

Katalógusszám

11-730

Statikus teherbírás [t]

1,5

Minimális magasság [mm]

85

Maximális magasság [mm]

355

Tömeg [kg]

15,3

KÖRNYEZETVÉDELEM

A termékeket tilos a háztartási hulladékok között elhelyezni, hanem

ártalmatlanításra át kell azokat adni a megfelelő üzemeknek. Az

újrafeldolgozásra nem kerülő termék potenciális veszélyt jelent a

környezet és az emberek egészsége számára.

A „Topex Csoport Korlátolt felelősségű társaság” Betéti társaság, székhelye:

Warszawa, ul. Pograniczna 2/4 (továbbiakban: „Topex Csoport”) közli, hogy a jelen

utasítás (továbbiakban: „Utasítás“) tartalmával kapcsolatos mindennemű szerzői

jogok, beleértve a szövegre, benne lévő fényképekre, vázlatokra, rajzokra, valamint

kialakítására vonatkozóakat, kizárólagosan a Topex Csoportot illetik meg, és jogi

védelem alatt állnak, a szerzői jogról és szomszédos jogokról szóló 1994. február 4-i

törvény (azaz Hiv. Közl. 2006. évi 90 sz., 631. tétel, a későbbi változtatásokkal)

szerint. Az Utasítás egészének és egyes részeinek másolása, feldolgozása,

kereskedelmi célokból történő publikálása a Topex Csoport írásos beleegyezése

nélkül szigorúan tilos, és polgári, valamint büntetőjogi felelősségre vonást vonhat

maga után.

RO

MANUAL DE TRADUCERE (UTILIZATOR)

CRIC HIDRAULIC 11-730

ATENȚIE: CITIȚI CU ATENȚIE ACESTE INSTRUCȚIUNI ÎNAINTE

DE A UTILIZA UNEALTA ȘI PĂSTRAȚI ACESTE INSTRUCȚIUNI

PENTRU CONSULTĂRI ULTERIOARE.

Aceste instrucțiuni sunt o compilație de informații esențiale,

avertismente, note, descrieri operaționale și instrucțiuni de întreținere

și funcționare. Se recomandă să păstrați instrucțiunile de utilizare

împreună cu garanția și cu factura sau chitanța obținută în momentul

achiziției.

ATENȚIE: Cricul este proiectat pentru utilizare în interior.

"Produsul poate varia ușor în raport cu imaginile și descrierile din

manual”.

În ciuda utilizării unei structuri sigure prin proiectare, folosind măsuri

de protecţie și măsuri suplimentare, există întotdeauna un risc rezidual

de rănire în timpul lucrului.

• Cricul are o durată de viață de 10.000 de operațiuni. Nu utilizați cricul

după durata de funcționare specificată de producător.

• Cricul nu este proiectat pentru ridicarea persoanelor, astfel de acțiuni

sunt interzise.

• La utilizarea cricului, utilizatorul este obligat să observe dispozitivul și

sarcina în timpul ridicării.

• La umplerea sau completarea sistemului hidraulic, este esențial să

folosiți lichidul recomandat de producător.

• Când utilizați cricul, respectați toate marcajele de pe cric. Asigurați-

vă că acestea sunt întotdeauna vizibile și lizibile.

• Recomandăm utilizarea uleiului hidraulic HVI 13 pentru cric

• Nu utilizați unealta în atmosfere explozive.

• Există riscul de rănire dacă mâinile sunt ținute în apropierea punctului

de ridicare, în special atunci când ridicați sau coborâți încărcături.

• Țineți mâinile departe de punctul de sprijin în timpul lucrului.

• În cazul în care cricul este deteriorat, există un pericol pentru

persoana care-l manevrează din cauza căderii necontrolate a

9

încărcăturii ridicate. Cricul poate fi utilizat numai pe o suprafață plană,

solidă și orientată orizontal.

• Asigurați-vă că elevatorul este poziționat în siguranță.

• Asigurați-vă că greutatea care urmează să fie ridicată este mai mică

decât capacitatea maximă de ridicare a cricului.

• Locul de lucru trebuie să fie păstrat în ordine și bine luminat.

Dezordinea și iluminatul slab contribuie la producerea de accidente.

• Fiți atenți la condițiile din locuil de lucru. Nu expuneți cricul la

umiditate.

• Păstrați zona de lucru liberă de obstacole, în special de copii. Țineți

copiii și persoanele aflate în preajmă departe de zona de lucru.

• Fiți atent atunci când operați cricului, deoarece distragerea atenției

vă poate face să pierdeți controlul cricului.

• Țineți cricul departe de copii atunci când nu este utilizat.

• Nu împrumutați cricul cu nimeni care nu este familiarizat cu el sau

care nu a citit aceste instrucţiuni de utilizare, cricul poate fi periculos în

mâinile unor utilizatori neinstruiți.

• Nu utilizați cricul în scopuri pentru care nu este destinat.

• Purtați echipament de protecție personală, ochelari de protecție și

mănuși. Utilizarea echipamentului individual de protecție, cum ar fi

încălțămintea antiderapantă, casca de protecție, protecție auditivă (în

funcție de tipul de instrument utilizat) - reduce riscul de rănire.

• Păstrați o poziție fermă și echilibrul în permanență. Aceasta vă va

permite un control mai bun asupra echipamentului în situații

neprevăzute.

• Verificați în mod regulat nivelul uleiului hidraulic, completați dacă este

necesar și înlocuiți uleiul uzat. Păstrați întotdeauna maneta cricului

curată, uscată și fără ulei sau grăsime pentru a asigura o prindere

fermă. Când lucrați cu cricul, fiți prevăzători și acționați cu prudență în

fiecare operațiune. Nu folosiți cricul când sunteți obosit sau sub

influența drogurilor sau a alcoolului. O clipă de neatenție în timpul

funcționării poate duce la vătămări corporale grave.

• Înainte de a începe lucrările, verificați starea cricului, fixarea

componentelor și dacă există fisuri vizibile. Nu folosiți cricul dacă

pompa hidraulică nu funcționează corect.

• Solicitați repararea cricului numai de către o persoană calificată,

folosind numai piese de schimb, astfel încât acesta să poată fi utilizat

în continuare în siguranță.

Avertisment: Cricul este destinat exclusiv ridicării. Suprafața pe care

trebuie așezat cricul trebuie să fie plană, fermă și orientată orizontal.

Înainte de a ridica, de exemplu, un vehicul, blocați roțile cu ajutorul

saboților și acționați frâna de mână. Este interzis să lucrați sub un

vehicul sau alt obiect care se află pe cric. Este esențial ca obiectul

ridicat (vehiculul) să fie asigurat cu suporturi fixe suplimentare pe care

întreaga încărcătură să se poată sprijini în siguranță. Asigurați-vă că

cricul este în stare bună de funcționare înainte de ridicare. Nu efectuați

nicio ajustare a supapei de siguranță.

COMPONENTELE CRICULUI

1. Suport

2. Pârghie de legătură

3. Pârghie de blocare

4. Supapă de siguranță

5. Supapă de siguranță (se găsește numai la unele modele cu

legătură)

6. Racord de pârghie

7. Capac de umplere cu ulei

8. Priză pentru lubrifierea știftului (se găsește numai la unele

modele de cric)

ATENȚIE! Este interzis să vă aflați sub un vehicul sprijinit pe cric.

Nu demontați cricul, deoarece acest lucru poate duce la

defecțiuni sau la deteriorarea cricului, ceea ce poate duce la

riscuri pentru sănătate sau viață.

PREGĂTIREA DE LUCRU

Îmbinați cele două părți ale pârghiei împreună, plasați pârghia pliată în

locașul pârghiei și fixați-o cu blocajul pârghiei înșurubat.

RIDICAREA:

Închideți supapa de purjare prin rotirea manetei în sensul acelor de

ceasornic. Asigurați vehiculul împotriva mișcărilor. Așezați cricul sub

vehicul, într-un loc adecvat (consultați manualul de utilizare specific

vehiculului). Folosind mișcări în sus și în jos, pompați maneta până

când vehiculul este ridicat la înălțimea dorită.

COBORÂRE:

Prin rotirea manetei, deschideți supapa de purjare (pentru a face acest

lucru, trebuie să rotiți LENT maneta spre stânga).

ATENȚIONARE! ROTIȚI MANETA ÎNCET! NU EFECTUAȚI MAI

MULT DE O ÎNTOARCERE COMPLETĂ. Când coborârea este

completă, scoateți cricul de sub vehicul.

Când coborârea este completă, scoateți cricul de sub vehicul.

OPERAREA ȘI ÎNTREȚINEREA

UMPLEREA ULEIULUI HIDRAULIC (FIG. 4):

Așezați cricul în poziție verticală. Mutați pistonul pompei în poziția

extrem de joasă. Îndepărtați capacul de cauciuc de pe cilindrul cricului.

Umpleți cricul cu ulei hidraulic. (Umpleți cu ulei până la marginea

inferioară a orificiului de umplere). Scoateți aerul din cric, așa cum este

descris mai jos (la "Scoaterea aerului din sistemul hidraulic").

Instalați capacul înapoi în cilindrul cricului.

ELIMINAREA AERULUI DIN SISTEMUL HIDRAULIC (PURJARE)

Aerul se acumulează în sistemul hidraulic, ceea ce determină o

scădere a eficienței cricului. Pentru a elimina aerul din sistemul

hidraulic, procedați după cum urmează:

Deschideți supapa de purjare,

Îndepărtați capacul din gaura din cilindrul cricului.

Pompați energic maneta de câteva ori pentru a elimina aerul. Închideți

supapa de purjare.

Montați capacul înapoi în orificiul din cilindrul cricului.

După purjare, cricul ar trebui să funcționeze corect. În caz contrar,

repetați procedura de purjare până când aceasta este finalizată.

PREVENIREA COROZIUNII

Evitați contactul cricului cu umiditatea. Dacă apare contactul cu

umezeala, ștergeți cricul și lubrifiați cu ulei toate părțile vizibile ale

cricului.

Lubrifiați periodic conexiunile știfturilor și șurubul de susținere a

cricului.

PROBLEMĂ

CAUZE

Cricul

nu

atinge

capaci

tatea

sa

nomin

ală

Cricul

cade

sub

sarcin

ă.

Scurg

eri de

ulei de

sub

capac

ul

orificiu

lui de

umple

re

Pom

pa

nu

ofer

ă

nicio

rezis

tenț

ă

Cricul

se

ridică și

se

coboar

ă sub

sarcină

Cricul

nu se

extinde

la

înălțime

a

maximă

X

X

Supapa de siguranță nu este

complet închisă.

X

X

X

Prea puțin ulei în cric. Îndepărtați

capacul de la orificiul de umplere

și adăugați ulei hidraulic curat.

X

Rezervorul este supraumplut.

Scoateți dopul de la orificiul de

umplere și scurgeți excesul de

ulei.

X

X

X

Aerul se află în sistemul de

cricului. Deschideți supapa de

purjare și depresurizați maneta

elevatorului de mai multe ori.

Închideți supapa de purjare.

Repetați procedura dacă este

necesar.

X

X

X

Supapele nu pot fi închise din

cauza unui corp străin. Trebuie

să se curețe supapele Coborâți

pârghia pistonului și închideți

supapa de purjare. Scoateți

manual pârghia pistonului cu

câțiva centimetri. Deschideți

supapa de purjare și apoi

împingeți viguros pârghia

10

pistonului înapoi în poziția

inferioară.

DATELE TEHNICE

Număr de catalog

11-730

Sarcina statică [t]

1,5

Înălțimea minimă [mm]

85

Înălțime maximă [mm]

355

Masa [kg]

15,3

PROTECȚIA MEDIULUI

Produsul cu nu poate fi aruncat împreună cu deșeurile menajere, ci

trebuie predat pentru reciclare unei întreprinderi specializate.

Produsul nereciclat reprezintă un pericol potențial pentru mediul

înconjurător și oameni.

„Grupa Topex Spółka z ograniczoną odpowiedzialnością” Spółka komandytowa

cu sediul în Varşovia, str. Pograniczna 2/4 (numită în continuare: „Grupa Topex”)

informează că toate drepturile de autor asupra conţinutului acestor instrucțiuni

(numite în continuare: "Instrucţiuni"), inclusiv textul, fotografiile, diagramele,

desenele, precum și compoziția sa, aparţin în exclusivitate Grupului Topex și fac

obiectul protecţiei juridice în conformitate cu Legea din 4 februarie 1994 privind

drepturile de autor și drepturile conexe (M. Legea 2006 Nr. 90 Poz. 631, cu

modificările ulterioare). Copierea, prelucrarea, publicarea, modificarea în scopuri

comerciale a întregii Instrucțiuni și a componentelor sale individuale, fără acordul

Grupului Topex exprimat în scris, este strict interzisă și poate atrage răspunderea

civilă și penală.

SK

PRÍRUČKA NA PREKLAD (POUŽÍVATEĽ)

HYDRAULICKÝ VÝŤAH 11-730

POZNÁMKA: PRED POUŽITÍM NÁSTROJA SI POZORNE

PREČÍTAJTE TENTO NÁVOD A ULOŽTE HO NA ĎALŠIE

POUŽITIE.

Príručka je súbor potrebných informácií, upozornení, tipov, popisov

prevádzky a pravidiel údržby a prevádzky. Odporúča sa uložiť pokyn

spolu so zárukou a faktúrou alebo faktúrou získanou v čase nákupu.

POZNÁMKA: Výťah sa používa na vnútorné použitie.

"Výrobok sa môže mierne líšiť, pokiaľ ide o obrázky a popisy

obsiahnuté v príručke."

Napriek použitiu dizajnu, ktorý je dizajnovo bezpečný, použitiu

ochranných opatrení a dodatočným ochranným opatreniam, vždy

existuje riziko reziduálnych poranení počas prevádzky.

• Životnosť výťahu je 10 000 operácií. Nepoužívajte výťah po životnosti

určenej výrobcom.

• Zdvihák nie je určený na zdvíhanie ľudí, takéto akcie sú zakázané.

• Pri používaní výťahu je používateľ povinný počas zdvíhania

dodržiavať zariadenie a zaťaženie.

• Pri plnení alebo dopĺňaní hydraulického systému je nevyhnutné

použiť kvapalinu odporúčanú výrobcom

• Počas prevádzky zariadenia venujte pozornosť všetkým označeniam

na výťahu. Je potrebné dbať na to, aby boli vždy viditeľné a čitateľné.

• Pri výťahoch odporúčame používať hydraulický olej HVI 13

• Nástroj by sa nemal používať vo výbušnej atmosfére.

• Existuje riziko zranenia, ak držíte ruky v blízkosti podporného bodu

výťahu, najmä pri zdvíhaní a znižovaní hmotnosti.

• Pri práci nepribližujte ruky k opore.

• V prípade poškodenia výťahu hrozí nebezpečenstvo pre ľudí

nekontrolovaným zrážaním zdvihnutej hmoty. Výťah je možné použiť

len na rovnom a tvrdom horizontálne orientovanom povrchu.

• Uistite sa, že výťah je bezpečne umiestnený.

• Uistite sa, že zdvíhacia hmotnosť je menšia ako maximálna nosnosť

výťahu

• Udržujte pracovisko upratané a zabezpečte dobré osvetlenie.

Poruchy a zlé osvetlenie prispievajú k nehodám.

• Venujte pozornosť podmienkam na pracovisku. Nevystavujte výťah

vlhkosti.

• Pracovisko by malo byť chránené pred cudzincami, najmä deťmi.

Pozornosť by sa mala venovať a deti a okoloidúci by nemali byť

vpustení na pracovisko.

• Pri práci s výťahom by ste sa mali sústrediť, rozptýlenie môže

spôsobiť, že stratíte kontrolu nad výťahom.

• Nepoužitý výťah sa má uchovávať mimo dosahu detí.

• Nezdieľajte výťah s ľuďmi, ktorí ho nepoznajú alebo ktorí nečítali

tento návod na obsluhu, výťah môže byť nebezpečný v rukách

netrénovaných používateľov.

• Výťah nepoužívajte na účely, na ktoré nie je určený.

• Noste osobné ochranné prostriedky, ochranné okuliare a rukavice.

Použitie osobných ochranných prostriedkov, ako sú: protišmyková

obuv, ochranná prilba, ochrana sluchu (v závislosti od typu použitého

nástroja) – znižuje riziko zranenia.

• Vždy by ste mali udržiavať určitú pozíciu pri zachovaní rovnováhy.

To umožní lepšiu kontrolu nad výťahom v nepredvídaných situáciách.

• Pravidelne kontrolujte stav hydraulického oleja a v prípade potreby

vynahradte nedostatok a vymeňte použitý olej. Zdvíhacia páka by

mala byť vždy udržiavaná čistá, suchá, bez stôp oleja alebo mastnoty

zaručuje bezpečnú rukoväť. Pri práci s jackom by ste mali byť

predvídaví a opatrní pri vykonávaní akejkoľvek činnosti. Nepracujte s

výťahom, keď ste unavení alebo pod vplyvom drog alebo alkoholu.

Chvíľka nepozornosti počas operácie môže spôsobiť vážne zranenia.

• Pred začatím prác skontrolujte technický stav výťahu, upevnenie

prvkov a to, či nie sú viditeľné trhliny. Je zakázané pracovať s

zdvihákom, v ktorom hydraulické čerpadlo nefunguje.

• Opravu výťahu by mala vykonávať len kvalifikovaná osoba s použitím

iba náhradných dielov, vďaka čomu bude naďalej bezpečná na

používanie.

Upozornenie: Výťah je určený len na zdvíhacie účely. Povrch, na

ktorom by mal byť výťah umiestnený, by mal byť plochý, tvrdý a

horizontálne orientovaný. Pred začatím zdvíhania, napr. vozidla, by sa

kolesá mali zamknúť výmenou klinov a mala by sa použiť parkovacia

brzda. Je zakázané pracovať pod vozidlom alebo iným objektom, ktorý

spočíva na výťahu. Absolútne zdvihnutý objekt (vozidlo), bezpečný s

ďalšími pevnými podperami, na ktorých môže bezpečne spočívať celá

hmotnosť. Pred pokračovaním v zdvíhaní sa uistite, že výťah je v

dobrom technickom stave. Nesmie sa vykonať žiadne nastavenie

bezpečnostného ventilu.

ZDVÍHACIE KOMPONENTY

1. Podporovať

2. Zdvíhacia páka

3. Zámok páky

4. Krvácajúci ventil

5. Bezpečnostný ventil (k dispozícii iba na niektorých modeloch

výťahu)

6. Zásuvka páky

7. Uzáver olejovej plnky

8. Kolíková mazacia zásuvka (k dispozícii iba na niektorých modeloch

zdviháka)

POZNÁMKA! Nezačínajte pracovať pod vozidlom podopretým na

výťahu.

Nerozoberajte výťah, môže to viesť k poruche alebo poškodeniu

výťahu, čo môže viesť k riziku straty zdravia alebo života.

PRÍPRAVA NA PRÁCU

Pripojte dve časti páčky k sebe, vložte zloženú páčku do zásuvky páky

a zaistite ju zámkom páky skrutkovaním do zámku.

ZVYŠOVANIE:

Zatvorte krvácajúci ventil otočením páčky doprava. Chráňte vozidlo

pred pohybom. Umiestnite výťah pod vozidlo na vhodné miesto

(pozrite si informácie uvedené v návode na použitie, vhodné pre

vozidlo). Pri pohyboch hore a dole pumpujte pákou, až kým sa vozidlo

nezvýši do požadovanej výšky.

OPUSTENIE:

11

Otočením páčky otvorte krvácajúci ventil (aby ste to dosiahli, musíte

pomaly otočiť páčku doľava).

VAROVANIE! OTÁČAJTE PÁČKU POMALY! OPUSTITE VOZIDLO

POMALY! NESMIE SA VYKONAŤ VIAC AKO JEDEN ÚPLNÝ

OBRAT.

Po dokončení spúšťania vyberte výťah spod vozidla.

PREVÁDZKA A ÚDRŽBA

HYDRAULICKÁ OLEJOVÁ VÝPLŇ (obr. 4):

Umiestnite výťah vertikálne. Presuňte piest čerpadla do nižšej

extrémnej polohy. Odstráňte gumový kryt z zdvíhacieho valca.

Naplňte výťah hydraulickým olejom. (Naplňte olejom na spodný okraj

otvoru výplne.) Odstráňte vzduch z výťahu, ako je popísané nižšie (v

časti "Odstránenie vzduchu z hydraulického systému").

Nasaďte kryt späť na zdvíhací valec.

ODSTRÁNENIE VZDUCHU Z HYDRAULICKÉHO SYSTÉMU

(ODVZDUŠŇOVANIE)

Vzduch sa hromadí v hydraulickom systéme, čo spôsobuje zníženie

účinnosti výťahu. Ak to chcete urobiť, odstráňte vzduch z

hydraulického systému podľa nasledujúcich krokov:

Otvorte krvácajúci ventil,

Odstráňte kryt z otvoru vo valci zdviháka.

Niekoľkokrát prudko nafúknite pákou, aby ste odstránili vzduch.

Zatvorte krvácajúci ventil.

Nainštalujte kryt späť do otvoru vo valci zdviháka.

Po odvzdušňovaní by mal výťah fungovať správne. Ak tomu tak nie je,

postup krvácania by sa mal opakovať, až kým nebude úspešný.

PREVENCIA KORÓZIE

Vyhnite sa kontaktu výťahu s vlhkosťou. Ak príde do kontaktu s

vlhkosťou, utrite výťah dosucha a namažte všetky viditeľné prvky

výťahu olejom.

Spoje kolíkov a nosná skrutka zdviháka by sa mali pravidelne mazať.

PROBLÉM

DÔVOD

Výťah

nedos

ahuje

meno

vitú

zdvíh

aciu

Výťah

je

zaťaž

ený

Únik

oleja

spod

krytu

otvoru

výplne

Čerp

adlo

neo

dolá

Pri

zaťažen

í sa

páčka

zdvihne

a zníži

Výťah

sa

nerozšir

uje do

plnej

výšky

kapac

itu

X

X

Krvácajúci ventil nie je úplne

uzavretý.

X

X

X

Príliš málo oleja vo výťahu.

Odstráňte kryt z otvoru výplne a

pridajte čistý hydraulický olej.

X

Nádrž preteká. Vyberte zátku z

otvoru výplne a vypustite

prebytočný olej.

X

X

X

Vzduch je v jackovom systéme.

Otvorte krvácajúci ventil a

niekoľkokrát nafúknite pomocou

zdvíhacej páky. Zatvorte

krvácajúci ventil. V prípade

potreby zopakujte postup.

X

X

X

Ventily nie je možné zatvoriť kvôli

prítomnosti cudzieho telesa.

Spláchnite ventily. Opustite tyč a

zatvorte vypúšťací ventil. Ručne

vytiahnite piestnu tyč na niekoľko

centimetrov. Otvorte vypúšťací

ventil a potom energicky zatlačte

tyč do spodnej polohy.

TECHNICKÉ ÚDAJE

Katalógové číslo

11-730

Statické zaťaženie [t]

1,5

Minimálna výška [mm]

85

Maximálna výška [mm]

355

Hmotnosť [kg]

15,3

OCHRANA ŽIVOTNÉHO PROSTREDIA

Výrobok by sa nemal likvidovať s domovým odpadom, ale mal by sa zlikvidovať

vo vhodných zariadeniach. Nerecyklovaný výrobok predstavuje potenciálne

riziko pre životné prostredie a ľudské zdravie.

"Grupa Topex Spółka z ograniczoną odpowiedzialnością" Spółka komandytowa so sídlom vo

Varšave, 2/4 Pograniczna Street (ďalej len "Topex Group") informuje, že všetky autorské

práva k obsahu tejto inštrukcie (ďalej len "Inštrukcie"), vrátane m.in jej textu, fotografií,

diagramov, výkresov, ako aj jej kompozícií, patria výlučne do skupiny Topex a podliehajú

právnej ochrane v súlade so zákonom zo 4. februára 1994, o autorských právach a súvisiacich

právach (t. j. Zbierka zákonov z roku 2006 č. 90 bod 631 v znení neskorších predpisov).

Kopírovanie, spracovanie, publikovanie, úprava na komerčné účely celej Inštrukcie, ako aj jej

jednotlivých prvkov, bez písomného súhlasu skupiny Topex, je prísne zakázané a môže viesť

k občianskoprávnej a trestnoprávnej zodpovednosti.

12

Deklaracja Zgodności WE

/EC Declaration of Conformity//Megfelelőségi Nyilatkozat EK/

/ES vyhlásenie o zhode//Prohlášení o shodě ES/

/ЕО декларация за съответствие//Declarația de conformitate CE/

/EG-Konformitätserklärung/

/Dichiarazione di conformità CE/

PL EN HU SK CS BG RO DE IT

Producent

/Manufacturer//Gyártó//Výrobca//Výrobce//Производител/

/Producător//Hersteller//Produttore/

Grupa Topex Sp. z o.o. Sp.k.

ul. Pograniczna 2/4, 02-285 Warszawa

Wyrób

/Product/

/Termék/

/Produkt/

/Produkt/

/Продукт/

/Produs/

/Produkt/

/Prodotto/

Podnośnik hydrauliczny

/Hydraulic jack/

/Hidraulikus emelő/

/Hydraulický zdvihák/

/Hydraulický zvedák/

/Хидравличен крик/

/Cric hidraulic/

/Hydraulischer Wagenheber/

/Martinetto idraulico/

Model

/Model//Modell//Model//Model//Модел//Model//Modell//Modello/

11-730

Nazwa handlowa

/Commercial name//Kereskedelmi név/

/Obchodný názov//Obchodního názvu/

/Търговско наименование// Nume comercial//Handelsname/

/Nome depositato/

NEO TOOLS

Numer seryjny

/Serial number//Sorszám//Poradové číslo/

/Výrobního čísla//Сериен номер//Număr de serie/

/Ordnungsnummer//Numero di serie/

00001 ÷ 99999

Niniejsza deklaracja zgodności wydana zostaje na wyłączną odpowiedzialność producenta

/This declaration of conformity is issued under the sole responsibility of the manufacturer/

/Ezt a megfelelőségi nyilatkozatot a gyártó kizárólagos felelőssége mellett adják ki/

/Toto vyhlásenie o zhode sa vydáva na výhradnú zodpovednosť výrobcu/

/Toto prohlášení o shodě se vydává na výhradní odpovědnost výrobce/

/Тази декларация за съответствие се издава на единствената отговорност на производителя/

/Această declarație de conformitate este emisă sub responsabilitatea exclusivă a producătorului/

/Diese Konformitätserklärung wird in der alleinigen Verantwortung des Herstellers ausgestellt/

/Questa dichiarazione di conformità viene rilasciata sotto la responsabilità esclusiva del produttore/

Opisany wyżej wyrób jest zgodny z następującymi dokumentami:

/The above listed product is in conformity with the following UE Directives://A fent jelzett termék megfelel az alábbi

irányelveknek:/

/Vyššie popísaný výrobok je v zhode s nasledujúcimi dokumentmi://Výše popsaný výrobek splňuje následující

dokumenty://Описаният по-горе продукт отговаря на следните документи://Produsul descris mai sus respectă

următoarele documente://Das oben beschriebene Produkt entspricht den folgenden Dokumenten://Il prodotto sopra

descritto è conforme ai seguenti documenti:/

Dyrektywa Maszynowa 2006/42/WE

/Machinery Directive 2006/42/EC/

/2006/42/EK Gépek/

/Smernica Európskeho Parlamentu a Rady 2006/42/ES/

/Směrnice Evropského Parlamentu a Rady 2006/42/ES/

/Директива за машините 2006/42/ЕО/

/Directiva 2006/42 / CE privind utilajele

/Maschinenrichtlinie 2006/42 / EG/

/Direttiva macchine 2006/42 / CE/

oraz spełnia wymagania norm:

/and fulfils requirements of the following Standards://valamint megfelel az alábbi szabványoknak://a spĺňa požiadavky://a

splňuje požadavky norem:/ /и отговаря на изискванията на стандартите:/ /și îndeplinește cerințele

standardelor://und erfüllt die Anforderungen der Normen://e soddisfa i requisiti delle norme:/

EN 1494:2000/A1:2008

Deklaracja ta odnosi się wyłącznie do maszyny w stanie, w jakim została wprowadzona do obrotu i nie obejmuje części składowych dodanych przez

użytkownika końcowego lub przeprowadzonych przez niego późniejszych działań. /This declaration relates exclusively to the machinery in the state

in which it was placed on the market, and excludes components which are added and/or operations carried out subsequently by the final user.//Ez a

nyilatkozat a gépnek kizárólag arra az állapotára vonatkozik, amelyben forgalomba hozták, és kizár minden olyan alkatrészt, amelyet hozzáadnak,

és/vagy olyan műveletet, amit a végső felhasználó ezt követően végez rajta.//Toto vyhlásenie sa vzťahuje výlučne na strojové zariadenie v stave, v

13

akom sa uvádza na trh, a nezahŕňa pridané komponenty a/alebo činnosti vykonávané následne koncovým používateľom.//Toto prohlášení se

vztahuje výlučně na strojní zařízení ve stavu, v jakém bylo uvedeno na trh, a nevztahuje se na součásti, které byly následně přidány konečným

uživatelem, nebo následně provedené zásahy konečného uživatele.//Тази декларация се отнася изключително за машината в състоянието,

в което е пусната на пазара, и изключва компоненти, които са добавени и / или операции, извършени впоследствие от крайния

потребител.//Această declarație se referă doar la mașina din starea în care a fost introdusă pe piață și nu acoperă componentele adăugate de

utilizatorul final sau acțiunile ulterioare efectuate de utilizatorul final.//Diese Erklärung bezieht sich nur auf die Maschine in dem Zustand, in dem sie

in Verkehr gebracht wurde, und gilt nicht für vom Endbenutzer hinzugefügte Komponenten oder nachfolgende vom Endbenutzer durchgeführte

Aktionen.//La presente dichiarazione si riferisce solo alla macchina immessa sul mercato e non copre i componenti aggiunti dall'utente finale o le

operazioni successive eseguite dall'utente finale./

Nazwisko i adres osoby mającej miejsce zamieszkania lub siedzibę w UE upoważnionej do przygotowania dokumentacji technicznej:

/Name and address of the person who established in the Community and authorized to compile the technical file://A műszaki dokumentáció

összeállítására felhatalmazott, a közösség területén lakóhellyel vagy székhellyel rendelkező személy neve és címe://Meno a adresa osoby alebo

bydliska v EÚ poverená zostavením technickej dokumentácie:// Jméno a adresu osoby pověřené sestavením technické dokumentace, přičemž tato

osoba musí být usazena ve Společenství://Име и адрес на лицето, което пребивава или е установено в ЕС, упълномощено да съставя

техническото досие://Numele și adresa persoanei care locuiește sau este stabilită în UE autorizată să întocmească dosarul tehnic://Name und

Anschrift der Person mit Wohnsitz oder Niederlassung in der EU, die zur Erstellung der technischen Akte berechtigt ist:// Nome e indirizzo della

persona residente o stabilita nell'UE autorizzata a compilare il fascicolo tecnico:/s

Podpisano w imieniu:

/Signed for and on behalf of:/

/A tanúsítványt a következő nevében és megbízásából írták alá/

/Podpísané v mene:/

/Podepsáno jménem:/

/Подписано от името на:/

/Semnat în numele:/

/Unterzeichnet im Namen von:/

/Firmato per conto di:/

Grupa Topex Sp. z o.o. Sp.k.

ul. Pograniczna 2/4

02-285 Warszawa

Paweł Kowalski

Pełnomocnik ds. jakości firmy GRUPA TOPEX

/GRUPA TOPEX Quality Agent/

/A GRUPA TOPEX Minőségügyi meghatalmazott

képviselője/

/Splnomocnenec Kvalita TOPEX GROUP/

/Zástupce pro Kvalitu TOPEX GROUP/

/Качествен представител на GRUPA TOPEX/

/Reprezentant de calitate al GRUPA TOPEX/

/Qualitätsbeauftragter von GRUPA TOPEX/

/Rappresentante della qualità di GRUPA TOPEX/

Warszawa, 2022-05-12

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

w innych językach

- slovenčina: NEO TOOLS 11-730 Návod na obsluhu

- română: NEO TOOLS 11-730 Manualul proprietarului

Powiązane dokumenty

-

NEO TOOLS 11-732 Instrukcja obsługi

NEO TOOLS 11-732 Instrukcja obsługi

-

NEO TOOLS 11-700 Instrukcja obsługi

NEO TOOLS 11-700 Instrukcja obsługi

-

NEO TOOLS 10-452 Instrukcja obsługi

NEO TOOLS 10-452 Instrukcja obsługi

-

NEO TOOLS 10-596 Instrukcja obsługi

NEO TOOLS 10-596 Instrukcja obsługi

-

NEO TOOLS 81-617-S Instrukcja obsługi

NEO TOOLS 81-617-S Instrukcja obsługi

-

NEO TOOLS 97-361 Instrukcja obsługi

NEO TOOLS 97-361 Instrukcja obsługi

-

NEO TOOLS 99-038 Instrukcja obsługi

NEO TOOLS 99-038 Instrukcja obsługi

-

NEO TOOLS 99-076 Instrukcja obsługi

NEO TOOLS 99-076 Instrukcja obsługi

-

NEO TOOLS 99-045 Instrukcja obsługi

NEO TOOLS 99-045 Instrukcja obsługi

-

NEO TOOLS 63-142 Instrukcja obsługi

NEO TOOLS 63-142 Instrukcja obsługi

Inne dokumenty

-

Topex 94W120 Instrukcja obsługi

-

Stanley STMT81251-1 Instrukcja obsługi

-

Facom DL.200SECUA Instrukcja obsługi

-

USAG 2550 B Instrukcja obsługi

-

Facom DL.32A Instrukcja obsługi

-

Facom DL.PL10A Instrukcja obsługi

-

Facom DL.200SECU Instrukcja obsługi

-

Facom DL.30BTA Instrukcja obsługi

-

Facom DL.15AL Instrukcja obsługi

-

top tools 07A206 Instrukcja obsługi

top tools 07A206 Instrukcja obsługi