Variable speed

WH 12DM2 • WR 12DM2

Cordless Impact Driver/Wrench

Akku-Schlagschrauber

¢Ú··ÓÔηÙÛ¿‚È‰Ô ª·Ù·Ú›·˜/∫ÏÂȉ›

Bezprzewodowa wkrętarka udarowa

Akkus ütvecsavarozó/Csavarkulcs

Rázový utahovák/Klíč

Akülü darbeli vidalama/anahtar

ìÀapÌêÈ aÍÍyÏyÎÓÚopÌêÈ åypÔoÇepÚ

Read through carefully and understand these instructions before use.

Diese Anleitung vor Benutzung des Werkzeugs sorgfältig durchlesen und verstehen.

¢È·‚¿ÛÙ ÚÔÛÂÎÙÈο Î·È Î·Ù·ÓÔ‹ÛÂÙ ·˘Ù¤˜ ÙȘ Ô‰ËÁ›Â˜ ÚÈÓ ÙË ¯Ú‹ÛË.

Przed użytkowaniem należy dokładnie przeczytać niniejszą instrukcję i zrozumieć jej treść.

Használat előtt olvassa el figyelmesen a használati utasítást.

Před použitím si pečlivě přečtěte tento návod a ujistěte se, že mu dobře rozumíte.

Aleti kullanmadan önce bu kılavuzu iyice okuyun ve talimatları anlayın.

BÌËÏaÚeÎëÌo ÔpoäÚËÚe ÀaÌÌyï ËÌcÚpyÍáËï Ôo íÍcÔÎyaÚaáËË ÔpeÊÀe äeÏ ÔoÎëÁoÇaÚëcÓ ËÌcÚpyÏeÌÚoÏ.

Handling instructions

Bedienungsanleitung

√‰ËÁ›Â˜ ¯ÂÈÚÈÛÌÔ‡

Instrukcja obsługi

Kezelési utasítás

Návod k obsluze

Kullanım talimatları

àÌcÚpyÍáËÓ Ôo íÍcÔÎyaÚaáËË

1

2

1

1

4

3

6

5

87

H

1

E

D

2

3

2

1

4

5

8

7

6

1

8

7

6

A

B

9

0

C

E

CF

G

E

C

I

(UC14YFA)

(UC14YF2)

2 3

1211

14

13

M

O

N

109

16

15

J

(A)

5

4

1

(B)

2

3

K

L

3

J

P

J

R

Q

S

T

S

R

,

.

,.

3

U

L

R

VV

2019

21

1817

Z

W

X

Y

3mm

11.5mm

4

English Deutsch ∂ÏÏËÓÈο Polski

1

2

3

4

5

6

7

8

9

0

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

14.4 V Rechargeable

battery

Latch

Handle

Insert

Pull out

Insert

Pilot lamp

Hole for connecting the

rechargeable battery

Movement

Guide sleeve

Hexagonal hole in the

anvil

Driver bit

Hexagonal socket

Groove

Anvil

Pin

Ring

Hole

Plunger

Hook

Spring

Larger diameter faces

away

Switch

Phillips-head

screwdriver

Screw

Arrow

Hook cover

Indentation

Protuberance

AAAA batteries

Push button

Push

Wear limit

Nail of carbon brush

Protrusion of carbon

Contact portion outside

brush tube

14,4 V aufladbare

Batterie

Verriegelung

Handgriff

Einsetzen

Herausziehen

Einsetzen

Kontrollampe

Anschlußloch für

Ladebatterir

Bewegung

Führungsmanschette

Sechskantloch in der

Schabotte

Dreherspitze

Sechskantbuchse

Nut

Schabotte

Stift

Ring

Öffnung

Preßkolben

Haken

Feder

Der große Durchmesser

weist zur anderen Seite

Schalter

Kreuzschlitzschrauben-

zieher

Schraube

Pfeil

Hakenabdeckung

Einkerbung

Vorsprung

Batterien der Größe

AAAA

Druckknopf

Drücken

Verschließgrenze

Klaue der Kohlebürste

Krempe der Kohlebürste

Kontaktteil außerhalb

des Bürstenrohrs

14,4V ∂·Ó·ÊÔÚÙÈ˙fiÌÂÓË

Ì·Ù·Ú›·

ª¿Ó‰·ÏÔ

ÃÂÚÔ‡ÏÈ

∂ÈÛ¯ˆÚ‹ÛÙÂ

∆Ú·‚‹ÍÙ ¤Íˆ

∂ÈÛ¯ˆÚ‹ÛÂÙÂ

¢ÔÎÈÌ·ÛÙÈ΋ Ï¿Ì·

∆Ú‡· ÁÈ· ÙËÓ Û‡Ó‰ÂÛË

Ù˘ ·ӷÊÔÚÙÈ˙fiÌÂÓ˘

Ì·Ù·Ú›·˜

∫›ÓËÛË

√‰ËÁËÙÈÎfi˜ ‚Ú·¯›ÔÓ·˜

∂Í¿ÁˆÓË ÙÚ‡· ÛÙÔÓ

¿ÎÌÔÓ·

§Â›‰· ΛÓËÛ˘

ª·ÎÚÈ¿ ˘Ô‰Ô¯‹

∞˘Ï¿ÎˆÛË

ÕÎÌÔÓ·˜

¶Â›ÚÔ˜

¢·ÎÙ‡ÏÈÔ˜

∆Ú‡·

ŒÌ‚ÔÏÔ

°¿ÓÙ˙Ô˜

∂Ï·Ù‹ÚÈÔ

∏ ÌÂÁ·Ï‡ÙÂÚË ‰È¿ÌÂÙÚÔ˜

‚ϤÂÈ ÚÔ˜ ¿ÏÏË

ηÙ‡ı˘ÓÛË

¢È·ÎfiÙ˘

∫·ÙÛ·‚›‰È ÎÂÊ·Ï‹˜

Phillips

µ›‰·

µ¤ÏÔ˜

∫¿Ï˘ÌÌ· ·ÁΛÛÙÚÔ˘

∞˘Ï¿ÎˆÛË

¶ÚÔÂÍÔ¯‹

∞∞∞∞ ̷ٷڛ˜

∫Ô˘Ì› ÒıËÛ˘

™ÚÒÍÂ

ŸÚÈÔ ÊıÔÚ¿˜

∫·ÚÊ› ηڂԢӷÎÈÔ‡

¶ÚÔÂÍÔ¯‹ ηڂԢӷÎÈÔ‡

∆Ì‹Ì· ·ʋ˜ ¤Íˆ ·fi

ÙÔ ÛˆÏ‹Ó· Ù˘ „‹ÎÙÚ·˜

Akumulator 14,4 V

Zapadka

Rączka

Włóż/wprowadź

Wyciągnij

Włóż/wprowadź

Lampka kontrolna

Otwór wsuwowy

akumulatora

Ruch

Tuleja prowadnicy

Otwór sześciokątny w

kowadle

Wkrętak

Gniazdo sześciokątne

Rowek

Kowadło

Kołek

Pierścień

Otwór

Trzpień ruchomy

Hak

Sprężyna

Większa średnica jest

odwrócona

Przełącznik (włącznik/

wyłącznik)

Wkrętak Philipsa/

zgniazdkiem krzyżykowym

Śruba/wkręt

Strzałka

Pokrywa haka

Nacięcie

Wypukłość

Baterie AAAA

Przycisk

Wcisnąć

Ogranicznik zużycia

Końcówka szczotek

węglowych

Wypukłość elementu

węglowego

Element kontaktowy na

zewnątrz komory szczotek

5

Magyar Čeština Türkçe PyccÍËÈ

1

2

3

4

5

6

7

8

9

0

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

14,4 V-os tölthet

ő

akkumulátor

Retesz

Markolat

Bedugni

Kihúzni

Bedugni

Jelzőlámpa

Nyílás a tölthető

akkumulátor

csatlakoztatásához

Mozgás

Vezetőhüvely

Hatszögletű nyílás a

szárban

Behajtófej

Hatszögletű befogópatron

Vájat

Szár

Csap

Gyűrű

Nyílás

Hengeres csap

Kampó

Rúgó

A nagyobb átmérő az

ellenkező irány felé néz

Kapcsoló

Keresztfejes (Phillips-)

csavarhúzó

Csavar

Nyíl

A kampó fedele

Bemélyedés

Kidudorodás

AAAA méretű

szárazelemek

Nyomógomb

Benyomni

Megengedett kopás

A szénkefe szöge

A szénkefe kidudorodó

része

Érintkező rész a szénkefe

csövén kívül

14,4V Akumulátor

Zámek

Držadlo

Zasunout

Zatáhnout

Zasunout

Indikátor

Otvor pro zasunutí

akumulátoru

Pohyb

Vodicí objímka

Šestihranný otvor v pevné

části

Hrot šroubováku

Šestihranný nástrčkový klíč

Drážka

Pevná část

Kolík

Kroužek

Otvor

Západkový čep

Páčka

Pružina

Větší průměr směřuje ven

Spínač

Křížový šroubovák

Šroub

Šipka

Kryt páčky

Prohlubeň

Výstupek

AAAA baterie

Tlačítko

Stisknout

Mez opotřebení

Cvoček uhlíkového

kartáčku

Výstupek uhlíku

Dotyková část mimo

trubičku kartáčku

14,4 V Íarj edilebilir

batarya

Mandal

Kol

Yerleßtirin

Çekin

Yerleßtirin

Kılavuz lamba

Íarj edilebilir bataryanın

takılacaåı delik

Hareket

Kılavuz segmanı

Örstekki altıgen delik

Tahrik ucu

Altıgen yuva

Yiv

Örs

Pim

Halka

Delik

Ótici

Askı

Yay

Büyük olan çap uzaåa

bakar

Íalter

Yıldız baßlı tornavida

Vida

Ok

Askı kapaåı

Girinti

Çıkıntı

AAAA piller

Kilit iånesi

Ótin

Aßınma sınırı

Kömür çivisi

Kömür çıkıntısı

Kömür tüpünün dıßındaki

temas bölümü

14,4 B aÍÍyÏyÎÓÚopÌaÓ

ÄaÚapeÓ

îËÍcaÚop

PyÍoÓÚÍa

BcÚaÇËÚë

BêÚaçËÚë

BcÚaÇËÚë

KoÌÚpoÎëÌaÓ ÎaÏÔa

OÚÇepcÚËe ÀÎÓ

ÔoÀÍÎïäeÌËÓ

aÍÍyÏyÎÓÚopÌoÈ ÄaÚapeË

èepeÏeçeÌËe

HaÔpaÇÎÓïçËÈ oÄoÀ

òecÚËÖpaÌÌoe

oÚÇepcÚËe Ç ÌaÍoÇaÎëÌe

HacaÀÍa åypyÔoÇepÚa

òecÚËÖpaÌÌoe ÖÌeÁÀo

KaÌaÇÍa

HaÍoÇaÎëÌÓ

òÚËÙÚ

KoÎëáo

OÚÇepcÚËe

èÎyÌÊep

KpïäoÍ

èpyÊËÌa

ÅoÎëåËÈ ÀËaÏeÚp

ÔoÇopaäËÇaeÚcÓ Ç

ÀpyÖyï cÚopoÌy

BêÍÎïäaÚeÎë

OÚÇepÚÍa c

ÍpecÚooÄpaÁÌoÈ

ÖoÎoÇÍoÈ

BËÌÚ

CÚpeÎÍa

KpêåÍa ÍpïäÍa

ìÖÎyÄÎeÌËe

BêcÚyÔ

AÍÍyÏyÎÓÚopÌêe

ÄaÚapeË AAAA

HaÊËÏÌaÓ ÍÌoÔÍa

HaÊaÚë

èpeÀeÎ ËÁÌoca

èoÀÔpyÊËÌeÌÌêÈ

ÍoÌÚaÍÚ yÖoÎëÌoÈ çeÚÍË

BêcÚyÔaïçaÓ äacÚë

yÖoÎëÌoÈ çeÚÍË

ìäacÚoÍ ÍoÌÚaÍÚa

cÌapyÊË çeÚoäÌoÈ

ÖËÎëÁê

English

6

GENERAL OPERATIONAL PRECAUTIONS

1. Keep work area clean. Cluttered areas and benches

invite accidents.

2. Avoid dangerous environment. Don’t expose power

tools and charger to rain. Don’t use power tools

and charger in damp or wet locations. And keep

work area well lit. Never use power tools and

charger near flammable or explosive materials.

Do not use tool and charger in presence of

flammable liquids or gases.

3. The appliance is not intended for use by young

children or infirm persons without supervision.

Young children should be supervised to ensure

that they do not play with the appliance. All visitors

should be kept safe distance from work area.

4. Store idle tools and charger. When not in use,

tools and charger should be stored in dry, high

or locked-up place-out of reach of the children and

infirm persons. Store tools and charger in a place

where the temperature is less than 40°C.

5. Don’t force tool. It will do the job better and safer

at the rate for which it was designed.

6. Use right tool. Don’t force small tool or attachment

to do the job of a heavy duty tool.

7. Wear proper apparel. Do not wear loose clothing

or jewelry. They can be caught in moving parts.

Rubber gloves and non-skid footwears are

recommended when working outdoor.

8. Use eye protection with most tools. Also use face

or dust mask if cutting operation is dusty.

9. Don’t abuse cord. Never carry charger by cord or

yank it to disconnect from receptacle. Keep cord

from heat, oil and sharp edges.

10. Secure work. Use clamps or a vise to hold work.

It’s safer than using your hand and it frees both

hands to operate tool.

11. Don’t overreach. Keep proper footing and balance

at all times.

12. Maintain tools with care. Keep tools sharp at all

times, and clean for best and safest performance.

Follow instructions for lubricating and changing

accessories.

13. When the charger is not in use, or when being

maintained and inspected, disconnect its power

cord from the receptacle.

14. Remove chuck wrenches and wrenches. Form habit

of checking to see that wrenches are removed

from tool before turning it on.

15. Avoid accidental starting. Don’t carry tool with

finger on switch.

16. To avoid danger, always use only the specified

charger.

17. Use only genuine HITACHI replacement parts.

18. Do not use power tools for applications other than

those specified in the Handling Instructions.

19. To avoid personal injury, use only the accessories

or attachment recommended in these handling

instructions or in the HITACHI catalog.

20. Let only the authorized service center do the

repairing. The Manufacturer will not be responsible

for any damages or injuries caused by repair by

the unauthorized persons or by mishandling of

the tool.

21. To ensure the designed operational integrity of

power tools and charger, do not remove installed

covers or screws.

22. Always use the charger at the voltage specified

on the nameplate.

23. Do not touch movable parts or accessories unless

the power source has been disconnected.

24. Always charge the battery before use.

25. Never use a battery other than that specified. Do

not connect a usual dry cell, a rechargeable battery

other than that specified or a car battery to the

power tool.

26. Do not use any transformer that has a booster.

27. Do not charge the battery from an engine electric

generator or DC power supply.

28. Always charge indoors. Because the charger and

battery heat slightly during charging, charge the

battery in a place not exposed to direct sunlight;

where the humidity is low and the ventilation is

good.

29. Before starting to work in a high place, pay

attention to the activities below to make sure

there are no people below.

30. Use the exploded assembly drawing on this

handling instructions only for authorized servicing.

31. If the supply cord is damaged, it must be replaced

by the manufacture or its service agent or a

similarly qualified person in order to avoid a

hazard.

PRECAUTIONS FOR CORDLESS IMPACT

DRIVER

1. This is portable tool for tightening and loosenig

screws. Use it only for these operation.

2. Use the earplugs if using for a long time.

3. One-hand operation is extremely dangerous; hold

the unit firmly with both hands when operating.

4. After installing the driver bit, pull lightly out the

bit to make sure that it does not come loose. If

the bit is not installed properly, it can come loose

during use, which can be dangerous.

5. Use the bit that matches the screw.

6. Tightening a screw with the impact driver at an

angle to that screw can damage the head of the

screw and the proper force will not be transmitted

to the screw. Tighten with this impact driver lined

up straight with the screw.

7. Always charge the battery at a temperature of 0

– 40°C. A temperature of less than 0°C will result

in over charging which is dangerous. The battery

cannot be charged at a temperature greater than

40°C.

The most suitable temperature for charging is that

of 20 – 25°C.

8. Do not use the charger continuously.

When one charging is completed, leave the charger

for about 15 minutes before the next charging of

battery.

9. Do not allow foreign matter to enter the hole for

connecting the rechargeable battery.

10. Never disassemble the rechargeable battery and

charger.

English

7

11. Never short-circuit the rechargeable battery. Short-

circuiting the battery will cause a great electric

current and overheat. It results in burn or damage

to the battery.

12. Do not dispose of the battery in fire.

If the battery is burnt, it may explode.

13. Do not insert object into the air ventilation slots

of the charger.

Inserting metal objects or inflammables into the

charger air ventilation slots will result in electrical

shock hazard or damaged charger.

14. Bring the battery to the shop from which it was

purchased as soon as the post-charging battery

life becomes too short for practical use. Do not

dispose of the exhausted battery.

15. Using an exhausted battery will damage the

charger.

PRECAUTIONS FOR CORDLESS IMPACT

WRENCH

1. This is a portable tool for tightening and loosening

bolts and nuts. Use it only for these operation.

2. Use the earplugs if using for a long time.

3. One-hand operation is extremely dangerous; hold

the unit firmly with both hands when operating.

4. Check that the socket is not cracked or broken.

Broken or cracked sockets are dangerous. Check

the socket before using it.

5. Secure the socket with the socket pin and the ring.

If the socket pin or ring securing the socket is

damaged, the socket may come off from the impact

wrench, which is quite dangerous. Do not use

socket pins or rings that are deformed, worn out,

cracked, or in any other way damaged. Always

make sure to install the socket pin and ring in

the correct position.

6. Check the tightening torque.

The appropriate torque for tightening a bolt

depends on the material the bolt is made of, its

dimensions, grade, etc.

Also, the tightening torque generated by this

impact wrench depends on the materials and

dimensions of the bolt, how long the impact

wrench is applied for the way in which the socket

is installed, etc.

Also the torque when the battery has just been

charged and when it is about to run out are

slightly different. Use a torque wrench to check

that the bolt has been tightened with the

appropriate torque.

7. Stop the impact wrench before switching the

direction of rotation. Always release the switch

and wait for impact wrench to stop before

switching the direction of rotation.

8. Never touch the turning part.

Do not allow the turning socket section to get near

your hands or any other part of your body. You

could be cut or caught in the socket. Also, be

careful not to touch the socket after using

continuously it for a long time. It gets quite hot

and could burn you.

9. Never let the impact wrench turn without a load

when using the universal joint.

If the socket turns without being connected to a

load, the universal joint causes the socket to turn

wildly.

You could get hurt or the movement of the socket

could shake the impact wrench so much as to

make you drop it.

10. Always charge the battery at a temperature of

0 – 40°C.

A temperature of less than 0°C will result in over

charging which is dangerous. The battery cannot

be charged at a temperature greater than 40°C.

The most suitable temperature for charging is that

of 20 – 25°C.

11. Do not use the charger continuously.

When one charging is completed, leave the charger

for about 15 minutes before the next charging of

battery.

12. Do not allow foreign matter to enter the hole for

connecting the rechargeable battery.

13. Never disassemble the rechargeable battery and

charger.

14. Never short-circuit the rechargeable battery.

Short-circuiting the battery will cause a great

electric current and overheat. It results in burn or

damage to the battery.

15. Do not dispose of the battery in fire.

If the battery burnt, it may explode.

16. Do not insert object into the air ventilation slots

of the charger.

Inserting metal objects or inflammables into the

charger air ventilation slots will result in electrical

shock hazard or damaged charger.

17. Bring the battery to the shop from which it was

purchased as soon as the post-harging battery life

becomes too short for practical use. Do not dispose

of the exhausted battery.

18. Using an exhausted battery wil damage the

charger.

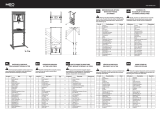

MODEL

WH12DM2: with charger and case

WR12DM2: with charger and case

English

8

SPECIFICATIONS

POWER TOOL

STANDARD ACCESSORIES

1. Charger (UC14YF2 or UC14YFA) .......................... 1

2. Plastic case ............................................................... 1

Standard accessories are subject to change without

notice.

OPTIONAL ACCESSORIES (sold separately)

〈For WH12DM2〉

1. Plus driver bit

2. Hexagonal socket

Model WH12DM2 WR12DM2

No-load speed 0 – 2600 min

–1

Capacity M4 – M8 (Small screw)

M6 – M16 (Ordinary bolt)

M5 – M12 (Ordinary bolt)

M6 – M12 (High tension bolt)

M5 – M10 (High tension bolt)

Tightening torque Maximum 135 N·m Maximum 165 N·m

{1375 kgf·cm} {1685 kgf·cm}

Tightening is M14 high tension bolt Tightening is M16(F10T), when fulley

(strength grade 12.9), when fulley charged at 20°C temp.

charged at 20°C temp. Tightening time: 3 sec.

Tightening time: 3 sec.

Rechargeable battery EB1220BL: Ni-Cd battery, 12 V (2.0 Ah 10 cells)

EB1230HL: Ni-MH battery, 12 V (3.0 Ah 10 cells)

Weight 1.6 kg

3. Wood working drill: Code No. 959183

CHARGER

Model

UC14YF2 UC14YFA

Charging time EB1220BL: Approx. 60 min. (at 20°C) EB1220BL: Approx. 50 min. (at 20°C)

EB1230HL: Approx. 90 min. (at 20°C) EB1230HL: Approx. 70 min. (at 20°C)

Charging voltage 7.2 – 14.4 V

Weight 1.3 kg 0.6 kg

Bit No. Code No.

No. 2 992671

No. 3 992672

Engraved characters

Part Name

Engraved

LBCode No.

characters

5 mm Hexagonal socket 8 65 8 996177

6 mm Hexagonal socket 10 65 10 985329

5/16" Hexagonal socket 12 65 12 996178

8 mm Hexagonal socket 13 65 13 996179

10 mm Hexagonal socket

14 65 14 996180

(small type)

10 mm Hexagonal socket 16 65 16 996181

10 mm Hexagonal socket 17 65 17 996182

1/2" Hexagonal long socket 21 166 21 996197

4. Drill chuck adapter set: Code No. 321823

Use the drills available on the local market.

English

9

Form B Form C

Form D

Code No.

High ISO ISO Inch

Form

tension

(ordinary)

(small) bolts L L1 øF

10 mm 944291 M6 10 B 40 8 18

12 mm 873632 M8 W5/16" 12 B 40 8 20

13 mm 873539 M8 13 B 40 9 25

12.7

Hexagonal

14 mm 873540 M10 14 B 40 9 25

Socket

17 mm 873536 M10 M12 W3/8" 17 C 32 8 28

19 mm 873624 M12 M14 W7/16" 19 C 34 9 28

21 mm 873626 W1/2" 21 D 36 10 32

22 mm 873627 M12 M14 M16 22 D 40 14 35

24 mm 873629 M16 M18 24 D 40 15 38

Square

head drive

dimensions

S (mm)

Part Name

Suitable Bolt Diameter

Hexagonal

width across

flats H (mm)

Main Socket

Dimensions (mm)

Form B Form C

Form D

2. Long Socket

Table 1

H S

L

L1

ØF

H S

L

L1

ØF

H S

L

L1

ØF

H

S

L1

L2

L

ØF

H S

L1

L2

L

ØF

H

S

L1

L2

L

ØF

Table 2

Code No.

High ISO ISO Inch

Form

tension

(ordinary)

(small) bolts L L1 L2 øF

12 mm 955138 M8 W5/16" 12 B 52 20 34 20

13 mm 955139 M8 13 B 52 20 34 21.5

14 mm 955140 M10 14 B 52 20 34 22

17 mm 955141 M10 M12 W3/8" 17 B 52 24 34 25

17 mm 955149 M10 M12 W3/8" 17 B 75 24 57 25

12.7

Long

19 mm 955142 M12 M14 W7/16" 19 B 52 24 34 28

Socket

19 mm 955150 M12 M14 W7/16" 19 B 75 24 57 28

21 mm 955143 W1/2" 21 D 52 24 34 31

21 mm 955151 W1/2" 21 D 75 24 57 31

21 mm 991480 W1/2" 21 D 125 24 107 31

22 mm 955144 M12 M14 M16 22 D 52 24 34 32.5

24 mm 955146 M16 M18 24 D 52 25 34 34

Square

head drive

dimensions

S (mm)

Part Name

Suitable Bolt Diameter

Hexagonal

width across

flats H (mm)

Main Socket

Dimensions (mm)

〈For WR12DM2〉

1. Sockets

English

10

3. Extension bar: Code No. 873633

The extension bar is convenient for working in very

restricted spaces or when the socket provided cannot

reach the bolt to be tightened.

CAUTION

when the extension bar is used, the tightening

torque is reduced slightly compared with the

ordinary socket.

4. Universal joint: Code No. 992610

The universal joint is convenient for impacting nuts

when there is an angle between the socket and

wrench, or when working in a very narrow space.

5. Duct Socket:

This is used for tightening bolts and nuts on flange

sections of air conditioners, type ducts, etc.

6. Corner attachment (Model EW-14R)

Use this attachment only when the machine is

applied to the nut or bolt at the right angle.

7. Bit adaptor: Code No. 991476

This is used for tightening small screws (M6 – M8).

NOTES

(1) This adaptor is set only on the anvil (drive angle)

of the main unit. The bit adapter cannot be attached

to the special accessory anvil (square drive).

(2) Before starting work with the adapter, tighten a few

screws with it to make sure it’s tightening with the

appropriate torque.

(3) Tightening speed will be greatly reduced when

driving wood, tapping or other similar screws.

䢇 Applicable plus driver bit

Optional accessories are subject to change without

notice.

APPLICATIONS

〈WH12DM2〉

䡬 Driving and removing of small screws, small bolts,

etc.

〈WR12DM2〉

䡬 Tightening and loosening of all types of bolts and

nuts, used for securing structural items.

BATTERY REMOVAL/INSTALLATION

1. Battery removal

Hold the handle tightly and push the battery latch

to remove the battery (Figs. 1 and 2).

CAUTION:

Never short-circuit the battery.

2. Battery installation

Insert the battery while observing its polarities (see

Fig. 2).

CHARGING

Before using the impact driver, charge the battery as

follows.

1. Connect the charger’s power cord to a receptacle.

When the power cord is connected, the charger’s

pilot lamp will blink in red (At 1-second intervals).

2. Insert the battery into the charger.

Insert the battery firmly, in the direction shown in

Figs. 3 and 4, until it contacts the bottom of the

charger compartment.

CAUTION:

䡬 If the battery is inserted in the reverse direction,

not only recharging will become impossible, but it

may also cause problems in the charger such as

a deformed recharging terminal.

Code No.

Hexagonal width

across flats (mm)

993658 12

992613 13

992615 14

Bit No. L (mm) Code No.

No. 2

45 955229

70 955654

No. 3

45 955230

70 955655

Bit No.

L 6.35

English

11

Lights for 0.5 seconds. Does not light for 0.5

seconds. (off for 0.5 seconds)

Lights continuously

Lights for 0.5 seconds. Does not light for 0.5

seconds. (off for 0.5 seconds)

Lights for 0.1 seconds. Does not light for 0.1

seconds. (off for 0.1 seconds)

Lights continuously

Before

charging

While

charging

Charging

complete

Charging

impossible

Blinks

(RED)

Lights

(RED)

Blinks

(RED)

Flickers

(RED)

Lights

(GREEN)

Malfunction in the

battery or the charger

The battery tempera-

ture is high, making

recharging impossible

Table 3

Indications of the pilot lamp

Charging

impossible

(2) Regarding the temperatures of the rechargeable

battery

The temperatures for rechargeable batteries are as

shown in the table below, and batteries that have

become hot should be cooled for a while before

being recharged.

Table 4 Recharging ranges of batteries

(3) Regarding recharging time

Depending on the combination of the charger and

batteries, the charging time will become as shown

in Table 5.

Table 5 Charging time (At 20°C)

NOTE

The charging time may vary according to the ambient

temperature and power source voltage.

4. Disconnect the charger’s power cord from the

receptacle.

5. Hold the charger firmly and pull out the battery.

NOTE

Be sure to pull out the battery from the charger

after use, and then keep it.

Regarding electric discharge in case of new

batteries, etc.

As the internal chemical substance of new batteries

and batteries that have not been used for an

extended period is not activated, the electric

discharge might be low when using them the first

and second time. This is a temporary phenomenon,

and normal time required for recharging will be

restored by recharging the batteries 2 – 3 times.

How to make the batteries perform longer.

(1) Recharge the batteries before they become

completely exhausted.

When you feel that the power of the tool becomes

weaker, stop using the tool and recharge its battery.

If you continue to use the tool and exhaust the

electric current, the battery may be damaged and

its life will become shorter.

(2) Avoid recharging at high temperatures.

A rechargeable battery will be hot immediately after

use. If such a battery is recharged immediately after

use, its internal chemical substance will deteriorate,

and the battery life will be shortened. Leave the

battery and recharge it after it has cooled for a

while.

CAUTION

䡬 If the battery is charged while it is heated because

it has been left for a long time in a location subject

to direct sunlight or because the batetery has just

been used, the pilot lamp of the charger lights up

green. In such a case, first let the battery cool, then

start charging.

Temperatures at

Rechargeable batteries which the battery

can be recharged

EB1220BL –5°C – 60°C

EB1230HL 0°C – 45°C

Charger

UC14YF2 UC14YFA

Battery

EB1220BL

Approx. 60 min. Approx. 50 min.

EB1230HL

Approx. 90 min. Approx. 70 min.

3. Charging

When inserting a battery in the charger, charging

will commence and the pilot lamp will light

continuously in red.

When the battery becomes fully recharged, the pilot

lamp will blink in red. (At 1-second intervals.) (See

Table 3)

(1) Pilot lamp indication

The indications of the pilot lamp will be as shown

in Table 3, according to the condition of the charger

or the rechargeable battery.

English

12

䡬 When the pilot lamp flickers in red (at 0.2-second

intervals), check for and take out any foreign objects

in the charger’s battery installation hole. If there are

no foreign objects, it is probable that the battery

or charger is malfunctioning. Take it to your

authorized Service Center.

䡬 Since the built-in micro computer takes about 3

seconds to confirm that the battery being charged

with UC14YFA or UC14YF2 is taken out, wait for

a minimum of 3 seconds before reinserting it to

continue charging. If the battery is reinserted within

3 seconds, the battery may not be properly charged.

PRIOR TO OPERATION

1. Preparing and checking the work environment

Make sure that the work site meets all the conditions

laid forth in the precautions.

2. Checking the battery

Make sure that the battery is installed firmly. If it

is at all loose it could come off and cause an

accident.

3. Installing the bit (WH12DM2)

Always follow the following procedure to install

driver bit (Fig. 5).

(1) Pull the guide sleeve back.

(2) Insert the bit into the hexagonal hole in the anvil.

(3) Release the guide sleeve and it returns to its original

position.

CAUTION

If the guide sleeve does not return to its original

position, then the bit is not installed properly.

4. Selecting the socket matched to the bolt (WR12DM2)

Be sure to use a socket which is matched to the

bolt to be tightened. Using an improper socket will

not only result in insufficient tightening but also in

damage to the socket or nut.

A worn or deformed hex. or square-holed socket

will not give an adequate tightness for fitting to the

nut or anvil, consequently resulting in loss of

tightening torque.

Pay attention to wear of socket hole, and replace

before further wear has developed.

Finally, install the socket prescribed in Item 5. The

section on “Optional Accessories” details the

relationship between bolt sizes and sockets. Sockets

are named according to the dihedral width of the

hexagonal hole.

5. Installing a socket (WR12DM2)

Select the socket to be used.

䢇 Pin, O-ring type (Fig. 6 and 7)

(1) Align the hole in the socket with the hole in the

anvil and insert the anvil into the socket.

(2) Insert the pin into the socket.

(3) Attach the ring to the groove on the socket.

䢇 Plunger type (Fig. 8)

Align the plunger located in the square part of the

anvil with the hole in the hex. socket. Then push

the plunger, and mount the hex. socket on the anvil.

Check that the plunger is fully engaged in the hole.

When removing the socket, reverse the sequence.

HOW TO USE

1. Using the convenient hook

The convenient hook can be installed on the right

or left side and the angle can be adjusted in 5 steps

between 0° and 80°.

(1) Operating the hook

(a) Pull out the hook toward you in the direction

of arrow (A) and turn in the direction of arrow

(B) (Fig. 9).

(b) The angle can be adjusted in 5 steps (0°, 20°,

40°, 60°, 80°).

Adjust the angle of the hook to the desired

position for use.

(2) Switching the hook position

CAUTION

Incomplete installation of the hook may result in

bodily injury when used.

(a) Securely hold the main unit and remove the

screw using a slotted head screwdriver or a coin

(Fig. 10).

(b) Remove the hook and spring (Fig. 11).

(c) Install the hook and spring on the other side and

securely fasten with screw (Fig. 12).

NOTE

Pay attention to the spring orientation. Install the

spring with larger diameter away from you (Fig. 12).

(3) Using as an auxiliary light

(a) Press the switch to turn off the light.

If forgotten, the light will turn off automatically

after 15 minutes.

(b) The direction of the light can be adjusted within

the range of hook positions 1 – 5 (Fig. 13).

䡬 Lighting time

AAAA manganese batteries: approx. 15 hrs.

AAAA alkali batteries: approx. 30 hrs.

CAUTION

Do not look directly into the light.

Such actions could result in eye injury.

(4) Replacing the batteries

(a) Loosen the hook screw with a phillips-head

screwdriver (No. 1) (Fig. 14).

Remove the hook cover by pushing in the

direction of the arrow (Fig. 15).

(b) Remove the old batteries and insert the new

batteries. Align with the hook indications and

position the plus (+) and minus (–) terminals

correctly (Fig. 16).

(c) Align the indentation in the hook main body

with the protuberance of the hook cover, press

the hook cover in the direction opposite to that

of the arrow shown in Fig. 15 and then tighten

the screw.

Use commercially available AAAA batteries

(1.5 V).

NOTE

Do not tighten the screw excessively. Such action

could strip the screw threads.

English

13

CAUTION

䡬 Failure to observe the following can result in battery

leakage, rust or malfunction.

Position the plus (+) and minus (–) terminals

correctly.

Replace both batteries at the same time. Do not mix

old and new batteries.

Remove exhausted batteries from the hook

immediately.

䡬 Do not discard batteries together with normal trash

and do not throw batteries into fire.

䡬 Store batteries out of the reach of children.

䡬 Use batteries correctly in accordance with the battery

specifications and indications.

2. Check the rotational direction

The bit rotates clockwise (viewed from the rear

side) by pushing the R-side of the push button.

The L-side of the push button is pushed to turn the

bit counterclockwise (See Fig. 17) (The

L

and

R

marks are provided on the body.).

CAUTION

The push button can not be switched while the

impact driver is turning. To switch the push button,

stop the impact driver, then set the push button.

3. Switch operation

䡬 When the trigger switch is depressed, the tool

rotates. When the trigger is released, the tool stops.

䡬 The rotational speed can be controlled by varying

the amount that the trigger switch is pulled. Speed

is low when the trigger switch is pulled slightly and

increases as the trigger switch is pulled more.

4. Tightening and loosening screws (WH12DM2)

Install the bit that matches the screw, line up the

bit in the grooves of the head of the screw, then

tighten it.

Push the impact driver just enough to keep the bit

fitting the head of the screw.

CAUTION

Applying the impact driver for too long tightens the

screw too much and can break it.

Tightening a screw with the impact driver at an

angle to that screw can damage the head of the

screw and the proper force will not be transmitted

to the screw.

Tighten with this impact driver lined up straight

with the screw.

5. Number of screws tightenings possible (WH12DM2)

Please refer to the table below for the number of

screw tightened possible with one charge.

EB1230HL

These values may vary slightly, according to

surrounding temperature and battery characteristics.

6. Number of bolt tightened possible (WR12DM2)

Please refer to the table below for the number of

bolt tightened possible with one charge.

EB1230HL

These values may vary slightly, according to

surrounding temperature and battery characteristics.

NOTE

The use of the battery EB1230HL in a cold condition

(below 0 degree Centigrade) can sometimes result

in the weakened tightening torque and reduced

amount of work. This, however, is a temporary

phenomenon, and returns to normal when the

battery warms up.

OPERATIONAL CAUTIONS

1. Resting the unit after continuous work

After use for continuous bolt-tightening work, rest

the unit for 15 minutes or so when replacing the

battery. The temperature of the motor, switch, etc.,

will rise if the work is started again immediately

after battery replacement, eventually resulting in

burnout.

NOTE

Do not touch the protector, as it gets very hot

during continuous work.

2. Cautions on use of the speed control switch

This switch has a built-in, electronic circuit which

steplessly varies the rotation speed. Consequently,

when the switch trigger is pulled only slightly (low

speed rotation) and the motor is stopped while

continuously driving in screws, the components of

the electronic circuit parts may overheat and be

damaged.

3. Tightening torque

Refer to Fig. 22 and Fig. 23 for the tightening torque

of bolts (according to size), under the conditions

shown in Fig. 24. Please use this example as a

general reference, as tightening torque will vary

according to tightening conditions.

NOTE

䡬 If a long striking time is used, screws will be strongly

tightened. This may cause the screw to break, or

may damage the tip of the bit.

䡬 If the unit is held at an angle to the screw being

tightened, the head of the screw may be damaged,

or the specified torque may not be transmitted to

the screw. Always keep the unit and the screw

being tightened in a straight line.

4. Use a tightening time suitable for the screw

The appropriate torque for a screw differs according

to the material and size of the screw, and the

material being screwed etc., so please use a

tightening time suitable for the screw. In particular,

if a long tightening time is used in the case of

screws smaller than M8, there is a danger of the

screw breaking, so please confirm the tightening

time and the tightening torque beforehand.

Screw used No. of tightenings

Wood screw ø4 x 50

Approx. 790

(Soft wood)

Machine screw M8 x 16 Approx. 1750

Bolt used No. of tightenings

M12 Hightension bolt Approx. 180

English

14

5. Work at a tightening torque suitable for the bolt

under impact

The optimum tightening torque for nuts or bolts

differs with material and size of the nuts or bolts.

An excessively large tightening torque for a small

bolt may stretch or break the bolt. The tightening

torque increases in proportionate to the operaton

time. Use the correct operating time for the bolt.

6. Holding the tool

Hold the impact wrench firmly with both hands. In

this case hold the wrench in line with the bolt.

It is not necessary to push the wrench very hard.

Hold the wrench with a force just sufficient to

counteract the impact force.

7. Confirm the tightening torque

The following factors contribute to a reduction of

the tightening torque. So confirm the actual

tightening torque needed by screwing up some

bolts before the job with a hand torque wrench.

Factors affecting the tightening torque are as follows.

(1) Voltage

When the discharge margin is reached, voltage

decreases and tightening torque is lowered.

(2) Operating time

The tightening torque increases when the operating

time increases. But the tightening torque does not

increase above a certain value even if the tool is

driven for a long time (See Fig. 22 and 23).

(3) Diameter of bolt

The tightening torque differs with the diameter of

the bolt as shown in Fig. 22 and 23. Generally a

larger diameter bolt requires larger tightening torque.

(4) Tightening conditions

The tightening torque differs according to the torque

ratio; class, and length of bolts even when bolts

with the same size threads are used. The tightening

torque also differs according to the condition of the

surface of workpiece through which the bolts are

to be tightened. When the bolt and nut turn together,

torque is greatly reduced.

(5) Using optional parts (WR12DM2)

The tightening torque is reduced a little when an

extension bar, universal joint or a long socketis

used.

(6) Clearance of the socket (WR12DM2)

A worn or deformed hex or a square-holed socket

will not give an adequate tightness to the fitting

between the nut or anvil, consequently resulting in

loss of tightening torque.

Using an improper socket which does not match

to the bolt will result in an insufficient tightening

torque. Matching socket and bolt sizes are shown

in Table 1 and 2.

(7) Tightening torque varies, depending on the battery’s

charge level (WR12DM2).

Fig. 25 shows an example of the relationship

between tightening torque and the number of

tightenings, for WR12DM2. As shown, tightening

torque gradually weakens with the increase in the

number of tightenings. In particular, as the torque

decreases very close to the complete discharge (“a”

margin in graph), the unit’s impact weakens, the

number of time impacts declines and tightening

torque drops off abruptly. If this occurs, check torque

level, then recharge the battery if necessary.

Fig. 22

Tightening torque

Tightening torque

Tightening torque

Tightening time: sec

(Steel plate thickness

t = 10 mm)

Tightening time: sec

(Steel plate thickness

t = 25 mm)

Tightening time: sec

(Steel plate thickness

t = 25 mm)

1400

1200

1000

800

600

400

200

0

140

120

100

80

60

40

20

0

M14 × 50

0 123

kgf·cm N·m

1400

1200

1000

800

600

400

200

0

140

120

100

80

60

40

20

0

M12 × 45

0 123

kgf·cm N·m

1000

800

600

400

200

0

0 123

100

80

60

40

20

0

M10 × 30

kgf·cm N·m

High tension bolt

Ordinary bolt

Ordinary bolt

Ordinary bolt

High tension

bolt

High tension

bolt

English

15

Tightening time: sec

(Steel plate thickness

t = 10 mm)

Tightening time: sec

(Steel plate thickness

t = 25 mm)

Tightening time: sec

(Steel plate thickness

t = 25 mm)

Tightening torque

Tightening torque

Tightening torque

Fig. 23

2000

1500

1000

500

0

012 3

200

150

100

50

0

M10 × 30

kgf·cm N·m

2000

1500

1000

500

0

012 3

200

150

100

50

0

M12 × 45

kgf·cm N·m

2000

1500

1000

500

0

012 3

200

150

100

50

0

M14 × 50

kgf·cm N·m

Ordinary boltOrdinary bolt

High tension

bolt

High tension

bolt

Ordinary bolt

High tension

bolt

Nut Fig. 24

Explanation of strength grade:

4 — Yield point of bolt: 32 kgf/mm

2

8 — Pulling strength of bolt: 40 kgf/mm

2

*The following bolt is used.

Ordinary bolt: Strength grade 4.8

High tensile bolt: Strength grade 12.9

)(

Bolt

Steel plate thickness t

Tightening torque

Number of tightenings (PCS)/charging

Fig. 25

M16 × 55 F10T (tighening time 3 sec)

2000

1600

1200

800

400

0

020406080100 120 140

200

160

120

80

40

0

a

kgf·cm N·m

When full recharged

When completely

discharged

English

16

MAINTENANCE AND INSPECTION

1. Inspecting the driver bit (WH12DM2)

Using a broken bit or one with a worn out tip is

dangerous because the bit can slip. Replace it.

2. Inspecting the socket (WR12DM2)

A worn or deformed hex or a square-holed socket

will not give an adequate tightness to the fitting

between the nut or anvil, consequently resulting in

loss of tightening torque. Pay attention to wear of

a socket holes periodically, and replace with a new

one if needed.

3. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

4. Maintenance of the motor

The motor unit winding is the very "heart" of the

power tool.

Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

5. Inspecting the carbon brushes (Fig. 18)

The motor employs carbon brushes which are

consumable parts. Since and excessively worn

carbon brush can result in motor trouble, replace

the carbon brush with new ones when it becomes

worn to or near the "wear limit". In addition, always

keep carbon brushes clean and ensure that they

slide freely whthin the brush holders.

NOTE

When replacing the carbon brush with a new one,

be sure to use the Hitachi Carbon Brush Code No.

999054.

6. Replacing carbon brushes

Take out the carbon brush by first removing the

brush cap and then hooking the protrusion of the

carbon brush with a slotted head screw driver, etc.,

as shown in Fig. 20.

When installing the carbon brush, choose the

direction so that the nail of the carbon brush agrees

with the contact portion outside the brush tube.

Then push it in with a finger as illustrated in Fig.

21. Lastly, install the brush cap.

CAUTION

Be absolutely sure to insert the nail of the carbon

brush into the contact portion outside the brush

tube. (You can insert whichever one of the two nails

provided.)

Caution must be exercised since any error in this

operation can result in the deformed nail of the

carbon brush and may cause motor trouble at an

early stage.

7. Cleaning on the outside

When the impact driver is stained, wipe with a soft

dry cloth or a cloth moistened with soapy water.

Do not use chloric solvents, gasoline or paint thinner,

for they melt plastics.

8. Storage

Store the driver drill in a place in which the tempera

ture is less than 40°C and out of reach of children.

9. Service parts list

CAUTION

Repair, modification and inspection of Hitachi Power

Tools must be carried out by a Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools,

the safety regulations and standards prescribed in

each country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts may be changed without

prior notice.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

Information concerning airborne noise and vibration

The measured values were determined according to

EN50144.

The typical A-weighted sound pressure level:

95 dB (A)(WH12DM2)

96 dB (A)(WR12DM2)

The typical A-weighted sound power level:

108 dB (A)(WH12DM2)

109 dB (A)(WR12DM2)

Wear ear protection.

The typical weighted root mean square acceleration

value: 10.8m/s

2

(WH12DM2)

12.1m/s

2

(WR12DM2)

Deutsch

17

ALLGEMEINE VORSICHTSMASSNAHMEN

1. Den Arbeitsplatz stets sauber halten. Unaufger-

äumte Arbeitsplätze und Werkbänke erhöhen die

Unfallgefahr.

2. Gefährliche Umgebungen vermeiden. Die Maschine

und das Ladegerät keiner Feuchtigkeit aussetzen

oder an nassen Stellen benutzen. Achten Sie auf

einen hellen, wenn erforderlich gut beleuchteten

Arbeitsplatz. Maschine und Ladegerät niemals in

der Nähe von brennbaren oder explosiven

Materialien, Flüssigkeiten oder Gasen verwenden.

3. Das Gerät ist nicht für Verwendung durch Kinder

oder gebrechliche Personen ohne Aufsicht gedacht.

Kinder sollten beaufsichtigt werden, um

sicherzustellen, dass sie nicht mit dem Gerät

spielen. Alle Besucher sollten in sicherer

Entfernung vom Arbeitsbereich gehalten werden.

4. Unbenutztes Werkzeug und Ladegerät an einen

trockenen und verschlossenen Ort wegräumen;

außerhalb der Reichweite von Kindern und

gebrechlichen Personen aufbewahren. Die Temperatur

sollte weniger als 40°C betragen.

5. Das Werkzeug nicht überlasten. Es arbeitet sich

besser und sicherer bei angemessenen Gesch-

windigkeiten und Belastungen.

6. Das richtige Werkzeug zur Arbeit verwenden.

Erwarten Sie nicht, daß ein zu kleines Werkzeug

oder Zubehör die Arbeit einer Hochleistung-

smaschine verrichtet.

7. Achten Sie auf die richtige Kleidung. Lose oder

zu weite Kleidung bzw. und/oder Schmuck (z.B.

Ketten, Ringe, usw.) könnten sich in rotierenden

oder bewegenden Teilen verfangen. Schutzhand-

schuhe und Arbeitsschutzschuhe sind bei den

Arbeiten zu tragen.

8. Vergessen Sie nicht bei Arbeiten mit Werkzeugen

eine Sicherheitsbrille zu tragen, ebenfalls, wenn

erforderlich eine Gesichts- oder Staubmaske.

9. Schonen Sie das Anschlußkabel. Tragen Sie

niemals das Ladegerät am Kabel und ziehen Sie

nicht daran, um den Stecker von der Steckdose

zu trennen. Das Kabel gegen übermäßige Hitze,

Öl und scharfe Kanten schützen.

10. Das zu bearbeitende Werkstück gut sichern.

Zwingen oder Schraubstock für die Befestigung

des Werkstücks benutzen. Es erhöht die Sicherheit

und schafft freie Hände zur Bedienung des

Werkzeugs.

11. Verschaffen Sie sich einen festen Stand, er

garantiert Sicherheit und optimales Gleichgewicht

bei der Arbeit.

12. Das Werkzeug in gutem Zustand behalten. Stets

sauber halten, pflegen und warten, damit es immer

die beste Leistung bringt. Beachten Sie die

Anweisungen für Schmieren oder eventuelle

Auswechselungen.

13. Wird das Ladegerät nicht benutzt oder einer

Prüfung unterzogen, entfernen Sie den Stecker

aus Ihrem Wechselstro-manschluß.

14. Spannschlüssel und/oder Bohrfutterschlüssel vor

dem Gebrauch des Werkzeugs aus der Maschine

entfernen.

15. Zufälliges Einschalten vermeiden. Das Werkzeug

nicht mit dem Finger am Schalter tragen.

16. Um Gefahren zu vermeiden, verwenden Sie nur

das vorgeschriebene Ladegerät.

17. Nur Original-HITACHI-Ersatzteile verwenden.

18. Das Werkzeug und Ladegerät nicht anders als in

der Gebrauchsanweisung vorgeschrieben

verwenden.

19. Die Benutzung von Zubehör und Sonderzubehör,

die nicht im HITACHI-Katalog oder in der

Bedienungsanleitung aufgeführt sind, erhöhen das

Risiko von Verletzungen.

20. Reparaturen sollten nur in autorisierten HITACHI-

Service-Werkstätten durchgeführt werden. Der

Hersteller haftet nicht für Schäden und Unfälle,

die auf unautorisierte Fachkräfte oder auf den

Mißbrauch des Werkzeugs zurückgeführt werden

können.

21. Um den ursprünglichen Zustand des Werkzeugs

und Ladegerätes zu erhalten, entfernen Sie keine

Hinweisschilder, Abdeckungen oder Schrauben.

22. Nehmen Sie das Ladegerät immer nur mit der auf

dem Typenschild vorgeschriebenen Spannung in

Gebrauch.

23. Bewegliche Teile und Zubehöre nicht berühren,

wenn das Werkzeug nicht vom Netz abgetrennt

ist.

24. Immer vor der Benutzung die Batterie aufladen.

25. Nur die vorgeschriebene Batterie verwenden. Keine

gewöhnlichen Trockenbatterien oder Auto-

Batterien, für das Elektro-Werkzeug verwenden.

26. Keinen Transformator mit Puffersatz verwenden.

27. Die Batterie nicht an einem elektrischen Generator

oder einer Gleichstromversorgung aufladen.

28. Die Batterie immer drinnen aufladen. Da sich beim

Laden Ladegerät und Batterie erwärmen, an einem

Ort aufladen, der nicht direkter Sonnenbestrahlung

ausgesetzt und trocken ist.

29. Wenn an hochliegenden Stellen gearbeitet

wird,(z.B. Gerüst, Treppe) vergewissern Sie sich

vor Arbeitsbeginn, daß sich under Ihnen keiner im

Arbeits-bzw. Gefahrenkreis aufhält.

30. Die detaillierte Bestandsteilzeichnung, die der

Bedienungsanleitung beigefügt ist, ist nur für die

autorisierte Service-Werkstätte bestimmt.

31. Falls das mitgelieferte Kabel beschädigt wird, muss

es durch den Hersteller, seinen Kundendienstvertreter

oder eine ähnlich qualifizierte Person

ausgewechselt werden, um Gefahren zu

vermeiden.

VORSICHTSMASSNAHMEN FÜR DEN AKKU-

SCHLAGSCHRAUBER (WH12DM2)

1. Dies ist ein tragbares Werkzeuggerät zum Anziehen

und Lösen von Schrauben. Es sollte nur für diesen

Zweck eingesetzt werden.

2. Bei längerem Arbeiten Ohrstöpsel verwenden.

3. Es ist äußerst gefährlich, das Gerät nur mit einer

Hand zu bedienen. Das Gerät ist beim Betrieb mit

beiden Händen festzuhalten.

4. Nachdem das Schraubstück angebracht wurde,

sollte ein wenig daran gezogen werden, um

sicherzugehen, daß es festsitzt. Wenn das

Schraubstück nicht richtig aufgesetzt wird, kann

es sich während des Betriebs lösen, was

Verletzungsgefahr bedeutet.

5. Das Schrubstück gemäß der anzuziehenden

Schraube verwenden.

Wird ein Schraubstück benutzt, welches nicht

genau zur Schraube paßt, kann der Schraubenkopf

beschädigt werden.

Deutsch

18

6. Sollte versucht werden, mit dem Schlag-Schrauber

eine Schraube anzuziehen, wenn sich der Schlag-

Schrauber in einem Winkel zur Schraube befindet,

kann die Preßkraft des Geräts nicht voll zur Geltung

kommen; außer dem kann der Schraubenkopf

beschädigt werden. Anziehen, wenn sich der

Schlag-Schrauber mit der Schraube auf einer Linie

befindet.

7. Die Batterie immer bei einer Temperatur von

0 – 40°C laden. Laden bei einer Temperatur, die

niedriger als 0°C ist, wird gefährliche Überladung

verursachen. Die Batterie kann nicht bei einer

Temperatur oberhalb 40°C geladen werden.

Die beste Temperatur zum Laden wäre von 20 –

25°C.

8. Das Ladegerät nicht fortlaufend laden.

Nach Beendung einer Ladung, lassen Sie das

Ladegerät ungefähr 15 Minuten ruhen bevor die

nächste Batterieladung unternommen wird.

9. Keine Fremdkörper durch das Anschlußloch der

Batterie eindringen lassen.

10. Niemals die Batterie und das Ladegerät ausein-

andernehmen.

11. Niemals die Batterie kurzschließen. Kurzschluß der

Batterie verursacht eine zu große Stromzufuhr

und überhitzung, wodurch Durchbrennen oder

Schaden beider Batterie entsteht.

12. Die Batterie nicht ins Feuer werfen.

Sie könnte dabei explodieren.

13. Darauf achten, daß keine Gegenstände durch

Belüftungsschlitze des Aufladers in das Gerät

eindringen.

Wenn Metallobjekte oder entzündliche

Gegenstände durch die Belüftungsschlitze des

Aufladers eindringen, kann dies zu elektrischen

Schlägen führen oder den Auflader beschadigen.

14. Bringen Sie die Batterie zum Geschäft, wo Sie ihn

gekauft haben sobald die Lebensdauer der Batterie

abrinnt. Die erschöpfte Batterie nicht wegwerfen.

15. Benutzung verbrauchter Batterie beschädigt den

Auflader.

VORSICHTSMASSNAHMEN FÜR DEN

AKKU-SCHLAGSCHRAUBER (WR12DM2)

1. Dies ist ein tragbares Werkzeuggerät zum Anziehen

und Lösen von Schrauben. Es sollte nur für diesen

Zweck eingesetzt werden.

2. Bei längerem Arbeiten Ohrstöpsel verwenden.

3. Es ist äußerst gefährlich, das Gerät nur mit einer

Hand zu bedienen. Das Gerät ist beim Betrieb mit

beiden Händen festzuhalten.

4. Nachprüfen, ob die Buchse gesprungen oder

gebrochen ist. Gebrochene und gesprungene

Buchsen sind gefährlich, daher die Buchse vor

Gebrauch prüfen.

5. Die Buchse mit Buchsenstift und-ring sichern. Sollte

der Buchsenstift oder-ring beschädigt sein, kann

die Buchse vom Schlag-Schrauber geschleudert

werden, was gefährlich ist. Niemals Buchsenstifte

oder-ring verwenden, die deformiert, abgenutzt,

gesprungen oder sonstwie beschädigt sind. Immer

darauf achten, daß Buchsenstift und -ring in der

richtigen Position sind.

6. Das Anzugsdrehmoment prüfen.

Das geeignete Drehmoment für das Anziehen einer

Schraube hängt vom Material, der Art, den

Abmessungen, usw. der Schraube ab.

Außerdem hängt das von diesem Schlag-Schrauber

erzeugte Auzugsdrehmoment vom Material und

den Abmessungen der Schraube, für welche

zeitdauer der Schlag-Schrauber angewendet wird,

wie die Bushse angebracht ist, usw. ab. Das

Drehmomentvariiert auch leicht, wenn die Batterie

gerade aufgeladen wurde und wenn sie kurz vor

dem Erschöpfen steht. Mit einem

Anzugsdrehmomentschlüssel nachprüfen, ob die

Schraube mit dem richtigen Drehmoment

angezogen wurde.

7. Den Schlag-Schrauber zuerst stoppen, wenn die

Rotationsrichtung geändert werden soll.

Den Schalter immer erst freigeben und warten, bis

der Schlag-Schrauber stoppt, bevor auf die

entgegengesetzte Rotationsrichtung geschaltet

wird.

8. Niemals die rotierenden Teile berühren.

Darauf achten, daß sich der rotierende Buchsenteil

immer in genügendem Abstand zum Körper und

den Händen befindet, da die Gefahr besteht, sich

zu schneiden oder sich in der Buchse zu verfangen.

Die Buchse sollte auch nicht direkt nach langer

kontinuierlicher Benutzuntg berührt werden, da

durch die erzeugte Hitze Verbrennungsgefhr

besteht.

9. Den Schlag-Schrauber bei Benutzung des

Universalgelenks niemals ohne Einspannung

rotieren lassen.

Wenn sich die Buchse ohne eingespannt zu sein

dreht verusacht das Universalgelenk ein wildes

Rotieren der Buchse. Durch die schnelle Rotation

der Buchse kann der Schlag-Schrauber so stark

vibrieren, daß er losgelassen werden muß. Es

besteht hohe Verletzungsgefahr.

10. Die Batterie immer bei einer Temperatur von 0

- 40°C laden. Laden bei einer Temperatur die

niedriger als 0°C is twird gefährliche Überladung

verursachen. Die Batterie kann nicht bei einer

Temperatur über 40°C geladen werden. Die beste

Temperatur zum Laden wäre von 20 - 25°C.

11. Das Ladegerät nicht fortlaufend laden.

Nach Beendung einer Ladung, lassen Sie das

Ladegerät ungefähr 15 Minuten ruhen bevor die

nächste Batterieladung unternommen wird.

12. Keine Fremdkörper durch das Anschlußloch der

Batterie eindringen lassen.

13. Niemals die Batterie und das Ladegerät

auseinandernehmen.

14. Niemals die Batterie kurzschließen.

Kurzschluß der Batterie verursacht eine zu große

Stromzufuhr und Überhitzung, wodurch

Durchbrennen oder Schaden beider Batterie

ensteht.

15. Die Batterie nicht ins Feuer werfen. Sie könnte

dabei explodieren.

Deutsch

19

TECHNISCHE DATEN

ELEKTRO-WERKZEUG

Modell WH12DM2 WR12DM2

Leerlaufdrehzahl 0 – 2600 min

–1

Kapazität M4 – M8 (Kleine Schraube)

M6 – M16 (Üblicher Bolzen)

M5 – M12 (Üblicher Bolzen)

M6 – M12 (Hochzugfester Bolzen)

M5 – M10 (Hochzugfester Bolzen)

Spanndrehkraft Maximum 135 N·m Maximum 165 N·m

{1375 kgf·cm} {1685 kgf·cm}

Festspannen von M14 (Härtegrad 12,9) Anziehen ist M16 (F10T) bei voller

reißfeste Schraube bei voller Aufladung Ladung und einer Temperatur von 20°C.

und einer Temperatur von 20°C. Festspannungsdauer: 3 sec.

Festspannungsdauer: 3 sec.

Wiederaufladbare

EB1220BL: Ni-Cd Batterie, 12 V (2,0 Ah 10 Zellen)

Batterie

EB1230HL: Ni-MH Batterie, 12 V (3,0 Ah 10 Zellen)

Gewicht 1,6 kg

16. Darauf achten, daß keine Gegenstände durch

Belüftungsschlitze des Aufladers in das Gerät

eindringen.

Wenn Metallobjekte oder entzündliche

Gegenstände durch die Belüftungsschlitze des

Aufladers eindringen, kann dies zu elektrischen

Schlägen führen oder den Auflader beschädigen.

17. Bringen Sie die Batterie zum Geschäft, wo Sie ihn

gekauft haben sobald die Lebensdauer der Batterie

abrinnent. Die erschöpfte Batterie nicht wegwerfen.

18. Benutzung verbrauchter Batterie beschädigt den

Auflader.

MODELL

WH12DM2: mit Ladegerät und Gehäuse

WR12DM2: mit Ladegerät und Gehäuse

LADEGERÄT

Modell UC14YF2 UC14YFA

Ladedauer EB1220BL: Etwa. 60 min. (bei 20°C) EB1220BL: Etwa. 50 min. (bei 20°C)

EB1230HL: Etwa. 90 min. (bei 20°C) EB1230HL: Etwa. 70 min. (bei 20°C)

Ladespannung 7,2 – 14,4 V

Gewicht 1,3 kg 0,6 kg

STANDARDZUBEHÖR

1. Ladegerät (UC14YF2 oder UC14YFA) ................... 1

2. Plastikgehäus ............................................................ 1

Das Standardzubehör kann ohne vorherige

Bekanntmachung jederzeit geändert werden.

SONDERZUBEHÖR (separat zu beziehen)

〈Für WH12DM2〉

1. Plusschrauber

Schrauber Nr. Code-Nr.

Nr. 2 992671

Nr. 3 992672

2. Sechskantsteckhülse

Bezeichnung

Eingravierte

LBCode-Nr.

Zeichen

5 mm Sechskantmuffe 8 65 8 996177

6 mm Sechskantmuffe 10 65 10 985329

5/16'’ Sechskantmuffe 12 65 12 996178

8 mm Sechskantmuffe 13 65 13 996179

10 mm (Kleiner)

14 65 14 996180

Sechskantmuffe

10 mm Sechskantmuffe 16 65 16 996181

10 mm Sechskantmuffe 17 65 17 996182

1/2'’ longe Sechskant-

21 166 21 996197

muffe socket

Eingravierte Zeichen

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

Strona się ładuje...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

Hikoki WR 12DM2 Instrukcja obsługi

- Kategoria

- Wkrętaki mocy

- Typ

- Instrukcja obsługi

w innych językach

- slovenčina: Hikoki WR 12DM2 Používateľská príručka

- Türkçe: Hikoki WR 12DM2 Kullanım kılavuzu

Powiązane artykuły

Inne dokumenty

-

Hitachi WR 12DAF Handling Instructions Manual

-

Hitachi WR 22SA Handling Instructions Manual

-

Tryton TJKU30 Instrukcja obsługi

-

Hitachi WH 12DAF Handling Instructions Manual

-

Hitachi WH 18DL Handling Instructions Manual

-

Hitachi WH 14DL2 Handling Instructions Manual

-

Hitachi WR 14DBAL2 Handling Instructions Manual

-

Hitachi DS 14DL Handling Instructions Manual

-

Hitachi DS18DMR Handling Instructions Manual

-

NEO TOOLS 11-714 Instrukcja obsługi

NEO TOOLS 11-714 Instrukcja obsługi