3

GB

- Watch what you are doing, use common sense and do not operate the tool when you are tired

- Do not use a power tool while you are under the influence of drugs, alcohol or medication

WARNING: A moment of inattention while operating power tools may result in serious personal injury.

20 - Check damaged parts

- Before further use of tool, it should be carefully checked to determine that it will operate properly and perform its intended function

- Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting and any other conditions that may affect its

operation

- A guard or other part that is damaged should be properly repaired or replaced by an authorized service centre unless otherwise

indicated in this instruction manual

- Have defective switches replaced by an authorized service centre

WARNING: Do not use the tool if the on/off switch does not turn it on and off. The switch must be repaired before the tool is used.

21 - Have your tool repaired by a qualified person - This electric tool complies with the relevant safety rules. Repairs should only be carried

out by qualified persons, otherwise this may result in considerable danger to the user

WARNING: When servicing use only identical replacement parts.

WARNING: If the power cable is damaged it must be replaced by the manufacturer or an authorised service centre.

22 - Power tool mains plugs must match the mains socket - Never modify the plug in any way. Do not use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and matching sockets will reduce risk of electric shock

23 - If operating a power tool outside use a residual current device (RCD) - Use of an RCD reduces the risk of electric shock

NOTE: The term “residual current device (RCD)” may be replaced by the term “ground fault circuit interrupter (GFCI)” or “earth leakage circuit

breaker (ELCB)”.

WARNING: When used in Australia or New Zealand, it is recommended that this tool is ALWAYS supplied via Residual Current Device (RCD)

with a rated residual current of 30mA or less.

Router Table Safety

WARNING: ALWAYS wear personal protective equipment;

• Hearing protection to reduce the risk of induced hearing loss

• Respiratory protection to reduce the risk of inhalation of harmful dust

• Cut-proof no-fray gloves to avoid possible injuries when handling router cutters and rough material due to sharp edges.

Any gloves where fabric material can work loose with the possibility of fabric strands MUST not be used when operating the

router table

• Safety glasses to avoid eye injury caused by flying particles

Ensure all people in the vicinity of the work area use adequate protection. Keep bystanders a safe distance away.

WARNING: ALWAYS connect the dust extraction port on the router cutter guard to a suitable vacuum dust extraction system.

Certain types of wood are toxic or may cause allergic reactions in people and animals, especially when exposed to very fine dust. ALWAYS

wear appropriate respiratory protection in addition to vacuum dust extraction.

a) ONLY fit plunge routers that are listed as compatible in ‘Specification’ to the Router Table. Only fit router bits that are

suitable for the installed plunge router, with shanks compatible with the collet installed.

b) NEVER reach to the underside of the router table when the router is connected to the power supply.

c) ALWAYS remove the router plunge spring and plastic base plate, before fitting the tool to the router table.

This enables easy router bit change and height winder adjustment from above the table.

d) Keep your hands away from the cutting area. NEVER pass your hands directly over, or in front of, the revolving cutter.

As one hand approaches the router bit, move it AWAY from the cutter, in an arc motion over the top of the router bit, to the

out-feed side beyond the cutter. NEVER trail your fingers behind the workpiece and DO NOT use awkward hand positions.

Use push sticks and blocks where necessary.

e) Do not attempt to perform tasks on workpieces shorter than 300mm (12") in length without using special fixtures or

jigs. It is recommended to make work pieces oversize then cut to finished length.

f) ASSESS risks, benefits and alternatives BEFORE using push sticks, push blocks or other jigs and safety devices.

In many applications the use of such contraptions is useful and safe, however, in others it can be dangerous. Push sticks can

fly out of the operator’s hand, when they come into contact with the revolving router bit, potentially causing serious injuries.

g) ALWAYS support large workpieces on the in-feed and out-feed sides of the router table, and where necessary, also to

the sides. Use Triton Sliding Extension or Multi-stand wherever possible.

h) ALWAYS use guards, fences, horizontal and vertical featherboards etc., to guide the workpiece, counteract and avoid

kickback, especially when routing small or narrow workpieces. Vertical featherboards attached to the fence also help

prevent uncontrolled lift-up of the workpiece.

i) ALWAYS remove ALL loose objects from the table before operating. Vibrations may cause loose objects to move, and

come into contact with the cutter.

j) NEVER attempt to remove wood fragments or dust from the cutter with your hands, whilst the router bit is spinning.

ALWAYS switch the router off, disconnect the machine from the power supply, and wait until the cutter has come to a

standstill. ALWAYS use cut-proof gloves when touching the cutter, to avoid injury.

k) ALWAYS inspect the workpiece for nails, staples and other metal objects and foreign bodies. If the router cutter hits a

concealed nail, the bit may be destroyed, high-velocity projectiles may be produced, kickback can occur, all of which can lead

to serious injury.

l) WHEREVER possible, use blind cutting techniques, where the router bit does not protrude from underneath the

workpiece. Keeping the cutter on the underside of the workpiece provides additional operator protection.

m) ONLY expose the smallest possible part of the cutter above the table surface. Keep any unused portion of the cutter

below the table surface.

n) ALWAYS test any new setup by rotating the spindle by hand, with the machine disconnected from the

power supply. Ensure proper cutter clearance to the throat place, fence and guard, before starting the machine.

o) ALWAYS use suitable throat plates, providing optimum clearance around the router bit.

p) ALWAYS use the router cutter guard, and adjust the guard to cover as much of the router bit as possible, as close to the

workpiece as possible. This not only protects the user from accessing the revolving router cutter, it also provides effective

dust extraction

q) LIMIT the depth of cut; NEVER remove too much material in one pass. Several passes with at smaller cutting depth are

safer, and produce a better surface finish.

r) ENSURE to adjust the router cutter speed, according to router cutter diameter and material being cut. Use the speed

selection dial on the plunge router.

s) ALWAYS feed AGAINST the rotation of the cutter. Both feed direction and rotation are indicated by arrows on the

router table surface.

t) ALWAYS use the fence if using a cutter without bearing or pilot. ALWAYS support the workpiece firmly against the fence.

NEVER remove the retractable guards on the fence. ALWAYS use a cutter with bearing or pilot for freehand work.

Additional Safety Information

• ONLY use router cutters in perfect working condition compatible with the specification of the router table and which are

suitable for hand feeding operation (marked ‘MAN’ for manual operation according to EN 847-1)

• The bit must not enter the workpiece in the same direction as the feed direction. If this occurs, it is likely to cause climb

cutting, causing the workpiece to climb and pull away from the operator. This can lead to a loss of control and a potential

hazard during operation

• Do not attempt to re-sharpen router cutters unless you specifically follow the manufacturer’s instructions and have the

equipment to complete this task. The majority of router cutters have blades that cannot be re-sharpened and must be

replaced immediately if dull

• Do not create fence traps caused by improper fence location. Fence traps happen when the fence is positioned so far back that the front

side of the workpiece would be behind the router cutter. These are dangerous due to the risk of climb cutting and the difficulty of keeping

the workpiece against the fence

• Ensure the correct table insert (table ring) is fitted that is the correct size for the size of the router cutter fitted

• Never use a router table until fully assembled and always re-check fasteners after re-assembly after storage

• Make certain the router is not plugged into the power outlet when installing into the table or when making

adjustments or changing accessories

• DO NOT plug the router into a standard mains wall socket. It must be plugged into the router table switch box so it can be

switched off in an emergency

• The router table must be installed on a solid level surface and secured so the table will not tip. Use of auxiliary in-feed and out-feed

supports is necessary for long or wide workpieces. Long workpieces without adequate support could cause the table to tip towards the

operator causing injury

• Routers create a lot of vibration and can work loose from their mountings. Check the mountings frequently and re-tighten if

necessary

• Never start the tool with the router cutter already engaged in the workpiece. This can lead to a lack of control and possible injury

• The router table is designed to cut flat, straight and squared material only. Do not cut material that is warped, uneven, weak or made from

inconsistent material. If necessary make sure material is correctly prepared before use. Incorrect material can lead to a lack of control

and possible injury

WARNING: Unmaintained tools can cause uncontrolled situations. ONLY use router cutters that are correctly sharpened, maintained

and adjusted in accordance with the manufacturer’s instructions.

Note: Seek professional training and assistance before attempting work that require procedures you are not familiar with. STOP using the

router table, if, at any point during operation, you encounter difficulties or are uncertain how to proceed safely.

Product Familiarisation

1. Horizontal Featherboard T-Slot

2. Fence Face Spacer

3. Module Levelling Screw

4. Fence Micro-Adjuster

5. Vertical Featherboard

6. Guard Knob

7. Extraction Connector

8. Fence

9. Fence Knob

10. Table Scale

11. Module Levelling Screw

12. Thumb Hole

13. Featherboard Adjuster Knob

14. Fence Face

15. Module Mounting Rollers & Tracks

16. Cutter Height Winder Slot

17. Guard

18. Direction Indicator

19. Horizontal Featherboard

20. Featherboard T-Slot Knob

21. Featherboard Adjuster Knob

22. Module Levelling Bobbin Screw

23. Fence Face Adjustment Knob

24. Micro-Adjuster

25. Fence Slot

26. Fence Micro-Adjuster Knob

27. Table Scale Indicator

Intended Use

An effective router table capable of edge rebating, trenching, cross trenching, planing, edge moulding (fence and free hand), end grain work,

using a template guide, and morticing. For use with the Triton Workcentre TWX7 and Triton Routers.

Unpacking Your Tool

• Carefully unpack and inspect your new tool. Familiarise yourself with all its features and functions

• Ensure that all parts of the tool are present and in good condition. If any parts are missing or damaged, have such parts

replaced before attempting to use this tool

IMPORTANT: Read these instructions in combination with the instructions supplied with your Triton router and the Triton Workcentre.

For instruction video, please go to www.tritontools.com

Before Use

WARNING: Ensure the router is switched off and disconnected from the power supply before attaching or changing any accessories,

inserting or removing modules or making any adjustments.

Installing and removing the router module

See ‘Installing and removing modules’ in the main Workcentre TWX7 manual for a complete guide.

WARNING: Lower the router cutter to a safe height position before installing or removing the router table module.

WARNING: Some modules are heavy, especially with power tools installed. ALWAYS grip modules with both hands, ensure secure footing,

stand upright, and avoid awkward movements when removing and fitting modules

IMPORTANT: Always lower modules carefully using both the provided Thumb Holes. Uncontrolled lowering can cause Workcentre, module and

power tool damage as well as possible injury to the operator.

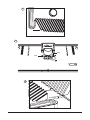

WARNING: Do not place fingers and/or body parts between the module and the Workcentre chassis. See Fig. L

To remove: Toggle the Module Locks to the unlocked position (see Fig. M). Using both Thumb Holes (12) to tilt the module to 45° then slide

and lift out

To insert: Locate the Module Mounting Rollers in the Module Mounting Tracks (15) as a hinging point and lower the insert down. Use the

Thumb Holes to lower to a level position and then re-lock the Module Locks

Note: Modules can be stood upright by angling them to around 120°. This position can be used when adjustments on the underside of

modules are necessary, e.g. adjustments to the fitted power tools, and there is no need to remove the module.

Assembling the router table module

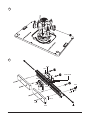

• Use the Figures provided; A-K to assemble the router table module. Step B requires additional information below.

Note: P1-6 on Fig.A is the Starting Pin for freehand operation and only requires fitting for freehand operation.

Fitting a Triton router to the router mounting plate

• The mounting plate is on the underside of the table and has been designed for direct mounting of any of the three

Triton Routers (JOF001, MOF001 and TRA001)

WARNING: Remove the plunge spring to configure the router for table-mounted operation. See the original router manual for procedure. Store

the spring carefully as it will need to be re-fitted when the router is removed from the router table module.

1. Remove the plastic cover of the base plate of the router by removing the securing screws. The screws and plastic base plate

should be safely stored for when they may need to be re-fitted in the future

2. Ensure the base of the router is completely clean so it will be level with the mounting plate when fitted

3. Loosen the two mounting knobs on the router until they are approximately 10mm above the base of the router when

pushed down

4. Push down on the mounting knobs until the bolt heads locate into the keyholes and rotate the router anticlockwise until the knobs align

with the small triangle holes (Fig. B)

5. Tighten the mounting knobs firmly

6. Ensuring all mains power is switched off, connect the power cable plug of the power tool to the mains socket of the

Workcentre not directly to a wall socket or other mains outlet

Note: Early Triton TRA001 routers do not feature a table winder connector.

Levelling the throat plate

1. Level the throat plate in the router table using a square and the supplied hex key to adjust the levelling screws (see Fig. N)

2. Fit the three Throat Plate Screws (P8) to secure the throat plate in position

3. Check the throat plate is level with the table surface

IMPORTANT: Always ensure the correct throat plate is used for the fitted router bit.

Levelling the router module

• All modules must be adjusted so they are level with the Workcentre chassis, to achieve accurate results and for safe

operation. Therefore all modules are equipped with seven Module Levelling Screws (11)

1. Fit the module into the Workcentre chassis and lock both Module Locks (20)

2. Tighten the three Module Levelling Bobbin Screws (11), until there is no movement between the module and the Workcentre

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

32

33

33

34

34

35

35

36

36

37

37

38

38

39

39

40

40

41

41

42

42

43

43

44

44

45

45

46

46

47

47

48

48

49

49

50

50

51

51

52

52

53

53

54

54

55

55

56

56

57

57

58

58

59

59

60

60

61

61

62

62

63

63

64

64

65

65

66

66

67

67

68

68